Haishu CK6180A: Revolutionizing Alloy Wheel Repair with Advanced Wheel Lathe Technology

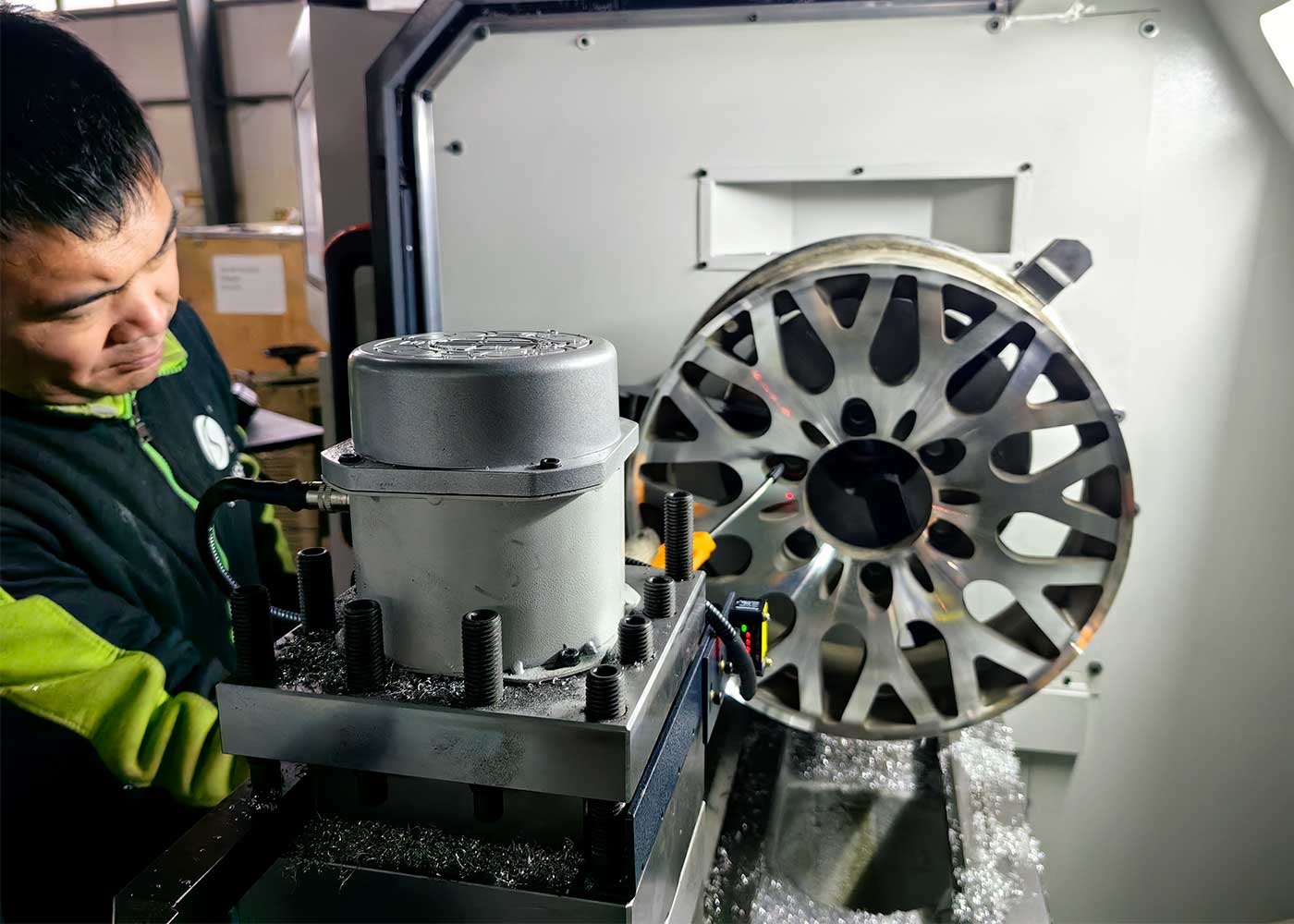

The Unmatched Precision of Haishu’s Wheel Lathe

In the realm of alloy wheel repair, Haishu’s CK6180A stands as a testament to engineering excellence. This sophisticated wheel CNC machine brings unparalleled precision and efficiency to the wheel repair industry, setting new standards for alloy wheel restoration.

Why is the CK6180A Wheel Repair Lathe a Game-Changer?

The CK6180A is more than a alloy wheel repair lathe; it embodies Haishu’s unwavering commitment to quality. Designed to handle wheels up to 35 inches, the CK6180A wheel repair machine offers precise and efficient restorations, ensuring every wheel is brought back to its original glory.

Enhanced Workflow with CK6180A’s Automatic Features

How Does the CK6180A Improve Repair Processes?

The CK6180A wheel repair lathe machine incorporates advanced features for precision profiling and automatic repair, allowing for seamless adaptation to a wheel’s curvature. This not only maintains the wheel’s original beauty but also streamlines the repair workflow, proving indispensable for any high-caliber wheel repair shop.

Delving into the CK6180A’s Precision Capabilities

Precision Profiling for Impeccable Repairs

Engineered for accuracy, the CK6180A wheel repair lathe leverages sophisticated data collection and programming optimization. This ensures that every wheel is machined to perfection, meeting the highest standards of alloy wheel repair.

Ensuring Safety and Precision

How does the CK6180A ensure the utmost safety during operation?

The CK6180A wheel repair machine features a manual jaw self-centering chuck, which firmly secures wheels in place. This crucial feature not only minimizes risks but also contributes significantly to the precision of each repair.

The Transformative Impact of CK6180A in South Korea

A South Korean auto repair shop experienced a remarkable transformation by integrating the CK6180A wheel CNC machine into their service offering. The shop owner, previously struggling to satisfy the growing demand for quality alloy wheel repairs, found that the CK6180A significantly boosted customer satisfaction and business growth.

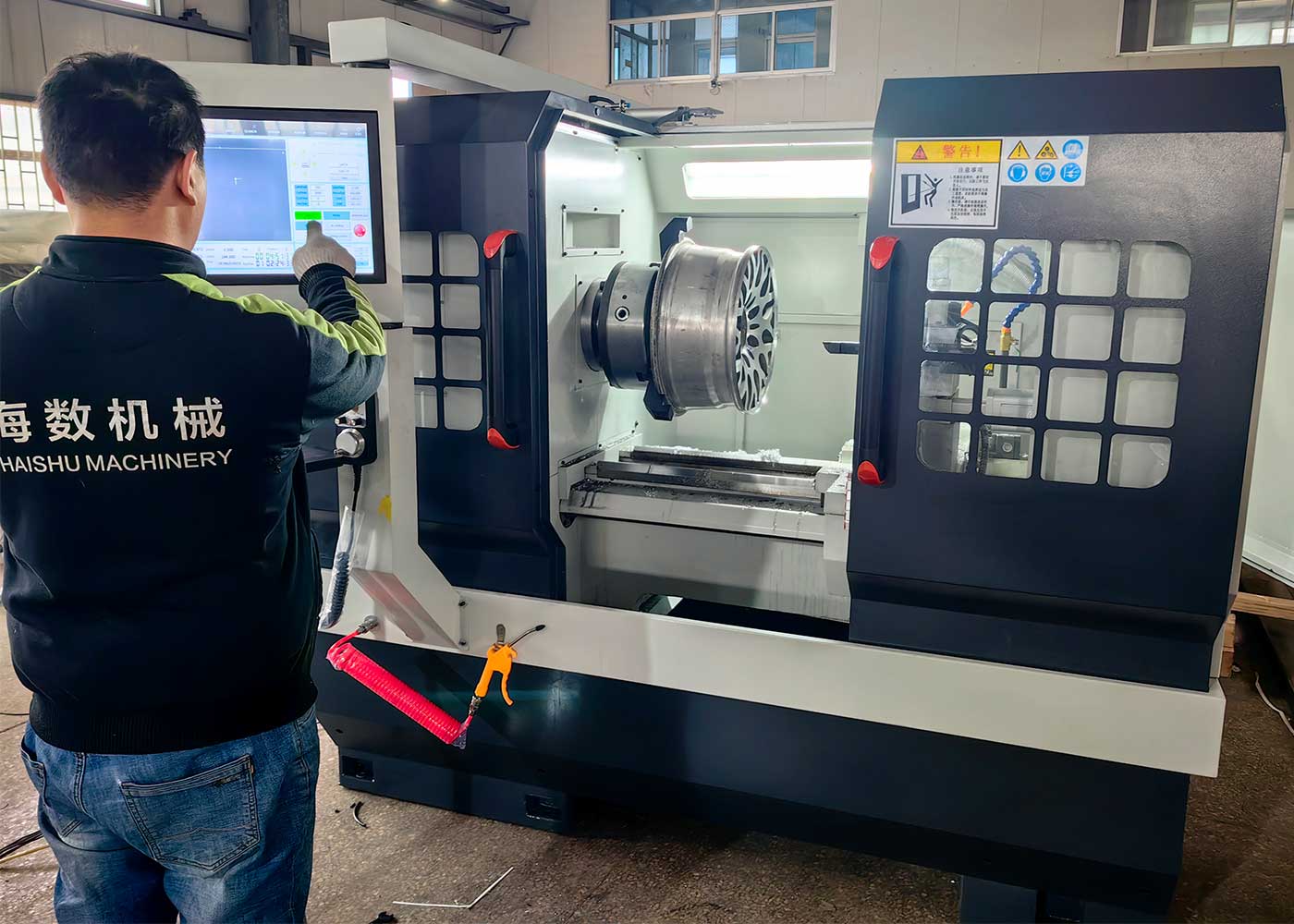

Advanced Control Systems of the CK6180A Wheel CNC Machine

What Makes the CK6180A’s Controls Stand Out?

The CK6180A is equipped with a spindle that allows for step-less speed adjustments and servo motors on the X/Z axis. These features grant the rim repair lathe machine exceptional control over the delicate process of wheel machining, setting it apart from other wheel repair lathes.

Haishu’s Global Presence and Commitment to Quality

How has Haishu Machinery’s Wheel Lathe Made a Global Impact?

With over 17 years in the industry, Haishu Machinery has marked its presence in over 30 countries. Their commitment to innovation and quality in producing wheel repair machines, including the CK6180A, has resonated globally.

Choosing Haishu’s CK6180A Wheel Lathe for Your Business

Why Opt for the CK6180A Wheel Repair Machine?

Selecting the CK6180A as your wheel repair CNC lathe means you’re investing in a legacy of precision. You’re not just buying a machine; you’re embracing a future where your wheel repair services are synonymous with excellence.

Does the CK6180A Comply with International Standards?

Indeed, the CK6180A wheel lathe meets international standards, backed by ISO9001 certification and CE approval. These credentials assure that Haishu’s wheel repair machines, including the CK6180A, adhere to the highest levels of quality and safety.

Conclusion

Embrace the future of alloy wheel repair with Haishu Machinery’s CK6180A wheel lathe. Offering unmatched precision and efficiency, this wheel repair machine is the partner you need to elevate your service offerings and stand out in the competitive wheel repair market. Explore the possibilities with the CK6180A and watch your business thrive.