Today’s automobile industry wheels are usually made of aluminum alloy wheels. All kinds of good looking wheels are precisely processed to improve their appearance. Forging, casting, brightening, painting, and other processes have indeed improved the car’s appearance and high-end sense. The car wheel is always rotating and sometime it will damage or collide by the roadside, so it is easily wearable. The more luxurious and exquisite models, the problems will be more conspicuous, so the car owners will spend a lot of money to repair the wheel hubs. In order to restore its effect, but is it actually effective? Is the operation complicated? It is said that in some cases repairing the wheel hub will also bring new potential crises. Today, I will give you a detailed answer to the technical job of wheel repair!

Under normal circumstances, the damage of aluminum alloy wheels can be basically divided into three categories according to the cause and extent of the damage.

The first type is abrasion on the surface and friction with the road teeth when parking on the side of the road.

The second type, major deformation, and distortion, is common in sudden encounters with large holes or high ridges at high speed.

The third type, fracture is common in impact and high-speed impact.

The repair methods for these three cases are also different, and the effects vary from person to person. Even some cases of repair will bring new dangers. What are the specifics? Keep watching!

The first type is surface wear repair, which is also our most common situation. Since it does not affect the force structure of the wheel hub, only the surface needs to be beautified. The process is also mature and worthy of repair.

The first step is sandblasting and polishing。

First of all, the wheel hub should be roughed and polished before repairing. The main method is to clean the wheel hub by sandblasting to lay a good foundation for subsequent beautification.

The second step, sandpaper polishing。

After most of the wheel hub has been treated by dust-free sandblasting, the next step is to use relatively fine water sandpaper to repeat the details again. You must be patient and whether it can be smooth and flat, this is the basis!

The third step is putty filling.

After the wheel hub is polished and leveled, alloy putty is used to fill in the scratches. This step is well understood. It is the same as filling up with putty for automobile sheet metal painting.

The difference is that alloy putty is used on the wheel hub, which is harder and more delicate than the ordinary putty used on car sheet metal.

The fourth step is aluminum welding fill.

This situation is common when the gap in the worn position is slightly larger and the putty filling effect is not good. Aluminum welding will be used to fill and level the aluminum alloy.

The fifth step is polishing.

Since the filling generally exceeds the original flat surface, the repair position needs to be polished so that the final metal remains roughly flat.

The sixth step is professional painting.

After finishing the surface treatment, it is time to paint. This step is just like the sheet metal spray painting of most repair shops, the difference is not big, and it is more a test of the color difference and uniformity of the spray paint. The master can better guarantee the final result.

The seventh step, lathe programming:

However, because the wheels of some models have bright surfaces and wire drawing processes, it is not possible to just polish them. They need to be processed by CNC machine tools. At this time, it is necessary to obtain very accurate details such as the correct curvature and spacing of the wheels to ensure the final result. Brushed effect.

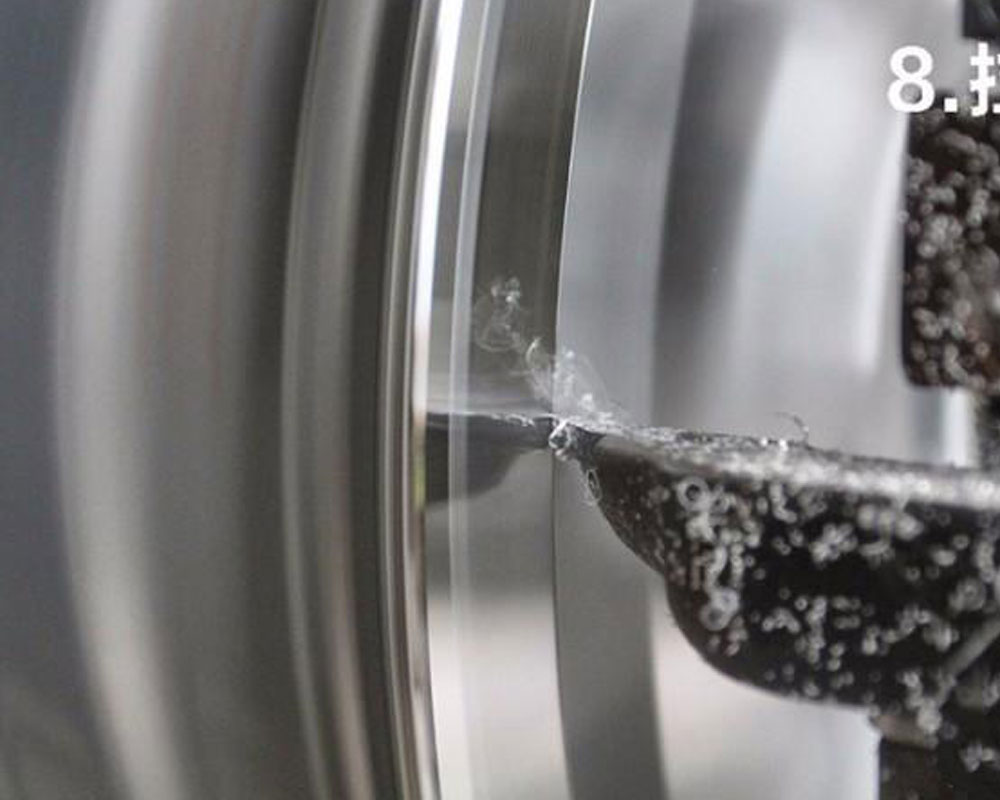

The eighth step, CNC wire drawing:

After programming, the wheel hub is finely cut with a lathe to ensure that the final surface is the same. In addition, since this step will reduce the thickness of the wheel hub, it is not suitable for multiple repairs, because the thinning of the wheel hub support surface will greatly affect the force performance of the wheel hub.

The ninth step, nano metal protective varnish:

After the previous steps are completed, the wheel hub needs to be sprayed with nano metal varnish, and after baking, it will be shinier and not easy to wear.

The tenth step, fine polishing:

Finally, the wheels are finely polished to make the effect shinier.

In addition to the second and third types of damage, due to changes in the structure of the hub, or even breakage, after this situation is repaired, the force capacity and internal structure of the hub itself are no longer as complete as before. The safety impact will be very large, so it is not recommended to repair the deformation.