What Makes the Alloy Cutting Wheel Repair Machine CK6166A Unique?

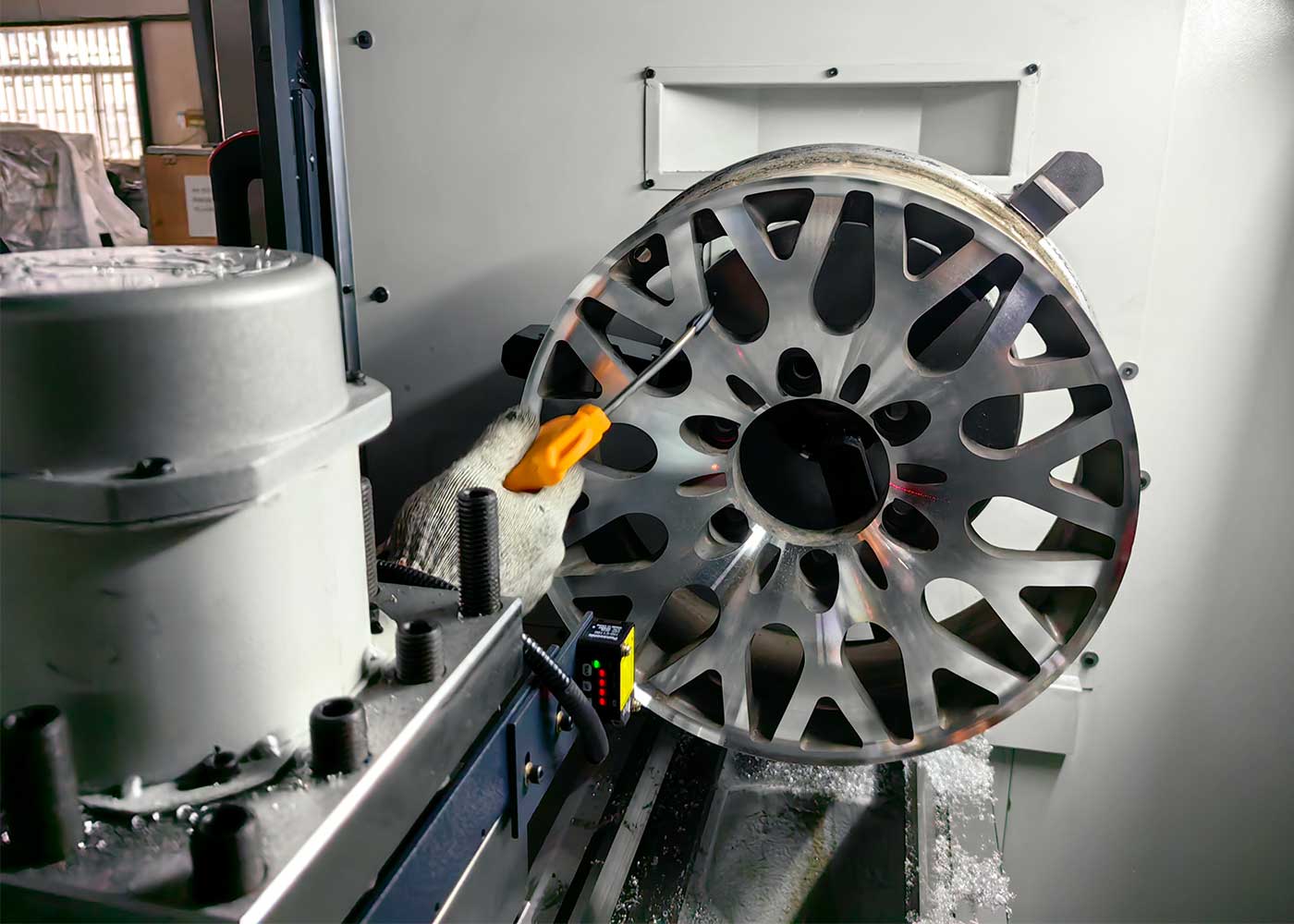

The Alloy Cutting Wheel Repair Machine CK6166A stands out in the automotive wheel refurbishment industry for its precision and efficiency. Designed for both production environments and repair shops, this wheel repair machine supports various machining, super-finishing, and maintenance tasks. Its robust structure, which includes a casting bed, precision spindle, and reliable fixing chuck, is complemented by an advanced numerical control system and top-quality servo motors, enhancing its performance and longevity.

How Does the Alloy Cutting Wheel Repair Machine CK6166A Optimize Wheel Repair?

The introduction of the CK6166A into the United States market highlights its global appeal. This Alloy Wheel CNC Machine is tailored to meet the demands of mid-sized repair facilities with features that promote ease of use and automation. Equipped with a user-friendly touchscreen interface, the CK6166A simplifies CNC control, allowing operators of varying skill levels to achieve superior results without intensive training.

What Advanced Features Does the Alloy Cutting Wheel Repair Machine CK6166A Offer?

The CK6166A is enriched with several innovative features that streamline the wheel repair process:

- Automatic laser scanning for precise measurements.

- Efficient data acquisition and storage.

- Self-developed CNC software that automatically optimizes programming.

- Multi-language support on a user-friendly touchscreen.

- X/Z-axis measurement for comprehensive treatment of wheel surfaces.

These features ensure the CK6166A meets the highest standards of wheel machining and refinishing.

How Does the Alloy Cutting Wheel Repair Machine CK6166A Enhance Repair Shop Capabilities?

Repair shops equipped with the CK6166A can expand their services to include sophisticated rim repair and wheel CNC machine operations. The machine’s Diamond Cutting Wheel Lathe feature allows for a premium finish on alloy wheels, boosting the quality of refurbishment services offered. Additionally, its versatility as a Vertical Wheel Repair Lathe ensures it can accommodate a wide range of wheel sizes and types, increasing its utility and appeal in diversified markets.

Conclusion: The Impact of the Wheel Reconditioning Lathe CK6166A on Future Wheel Repairs

The wheel refurbishment machine CK6166A is set to transform the future of wheel repair. By integrating advanced technology and comprehensive features, it offers a complete solution for wheel machining and refinishing. With the CK6166A, businesses are equipped to deliver high-quality service and achieve greater productivity, marking a significant advancement in the field of wheel refurbishment.