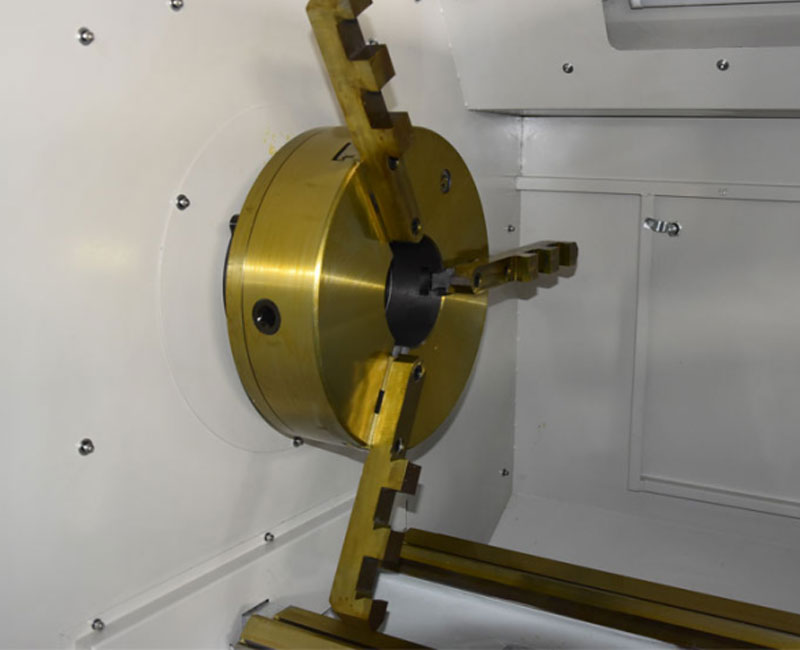

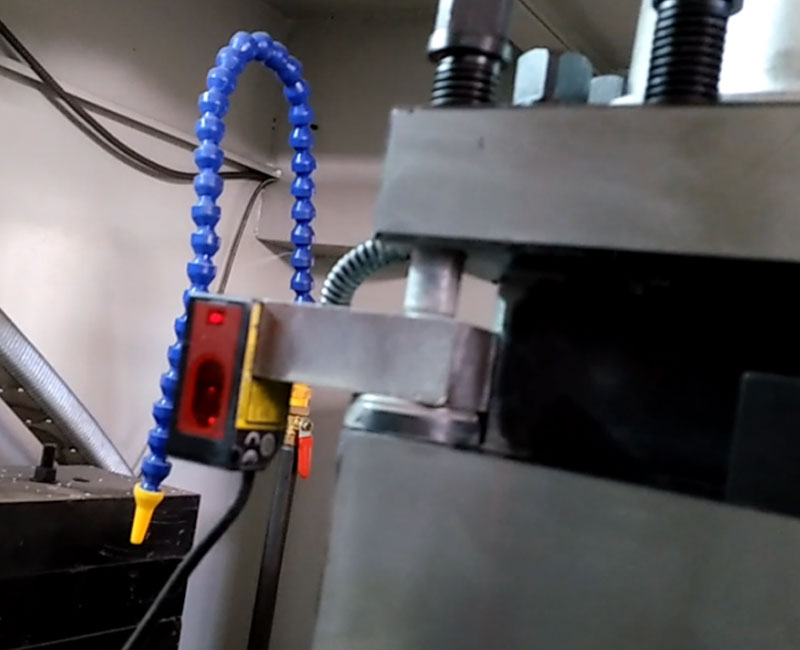

Alloy Wheel Polishing CNC Machine CK6190W is a Heavy Duty Wheel Repair Machine specially designed to process big wheels more than more than 30 inches. These car CNC wheel lathes are your best choice for wheel machining, super-finishing, and maintenance. CK6190W wheel CNC lathe is high precision, cost-effective and space-saving. Alloy wheel lathe CK6190W has the characteristics of high quality, high precision, and high efficiency and is composed of self-made mechanical parts such as the cast bed, spindle, fixing chuck and feeding mechanism, the imported numerical control system, the automatic measuring system, the famous brand servo motors and the auxiliary parts like lubrication, light, and cooling. Our wheel repair machine has detection scanning automatic programming wheel drawing machine. The Alloy Rim Repair CNC Lathe function is further improved on the basis of the original programming automatic wheel turning machine. No need for manual programming to measure curves which can be realized fully automatically.

This customer had already bought a wheel CNC lathe some days before, now his car repair company expanded its business, so he needed one more similar wheel CNC machine. But this time he needed a bigger model. After confirming the maximum wheel size, the customer stated that he needed the wheel lathe for the process max wheel size of about 30 inches. We recommended Alloy Wheel Polishing CNC Machine CK6190W to him, and he found it very suitable after checking the parameters. He asked for a PI directly and arranged to pay the deposit.

After the Alloy Wheel Polishing CNC Machine CK6190W, he expressed he very much trusts us and does not need to come to check. So we sent him the wheel repair lathe operation video and detailed pictures. He was very satisfied.

Alloy Wheel Polishing CNC Machine CK6190W Specifications

| Project name | Unit | Technical parameters |

| Machining wheel diameter | Inch | 30” |

| Max. workpiece length | mm | 750 |

| Probe measuring direction | X、Z | |

| Detection type | Laser | |

| Machining accuracy | IT6~IT7 | |

| Surface roughness | um | Ra0.8~1.6 |

| Main transmission form | Independent spindle; step-less frequency conversion | |

| Range of spindle speed | rpm | 150~2000 |

| Main motor power | kw | 11 |

| Fast-moving feed | mm/min | X – axis:5000 Z – axis:8000 |

| Repeat positioning accuracy | mm | X – axis:0.01 Z – axis:0.015 |

| Standard accessories | 4-station electric tool | |

| Repeat positioning accuracy(mm) | mm | 0.008 |

| Section of turning tool(mm) | mm | 25×25 |

Main Features of Alloy Wheel Polishing CNC Machine CK6190W

◆Wheel repair special CNC lathe. The new design, new structure, new technology.

◆Achieve the wheel surface profile measurement and data collection and Program Optimization.

◆Automatic precision repair and machining in accordance with the curve of the wheel surface.

◆Self-developed curve optimization software. Multilingual language interface. Installation and operation are simple.

◆Spindle frequency step-less speed.

◆X / Z axis servo drive.

◆Manual jaw self-centering chuck.

◆Machine guard full protection.

◆Security and fault alarm indication.

◆Automatic oil lubrication.

◆Diamond turning, to achieve high-precision smooth machining on the wheel surface.

3. Wheel Repair CNC Lathe Applications

◆The wheel CNC machine tool is suitable for High-precision turning and repair processing for the surface of the car wheel.

◆The wheel repair lathe has also the function of the general CNC lathes.

About Haishu Machinery

Taian Haishu Machinery Co., Ltd. is an Alloy Wheel Polishing CNC Machine designer and manufacturer dedicated in supplying automobile wheel production and repair solutions to worldwide customers. We have always worked hard to become the leader in designing and manufacturing CNC lathes since 2001. We have more than 30 talented experts and more than 12,000 square meters of factory.

Sticking on the product development ideas of innovation, simpleness, high quality, and high efficiency, we had been always focused on CNC software development, structural design, process planning, manufacturing deployment, and quality control since the foundation in 2001. Our innovative, high-quality products include Diamond Cut Alloy Machines, brake drum lathes, customized CNC machines, Alloy Wheel Polishing CNC Machines, wheel straightening machines, alloy wheel lathe machines, alloy wheel polishing machines, rim straightening machines, brake disc lathes, and other customized CNC machines. Our Diamond Cut Alloy Machine customers are from Germany, Russia, Spain, India, South Korea, Malaysia, Singapore, Saudi Arabia, South Africa, Iran, Indonesia, Turkey, Jordan, Dubai, Poland, Morocco, Mexico, Brazil, Lebanon, Thailand, Kazakhstan, Bangladesh, HK, Taiwan and so on. We are looking for partners all over the world.