What Is a Mobile Wheel Repair Lathe and How Does It Transform On-Site Services?

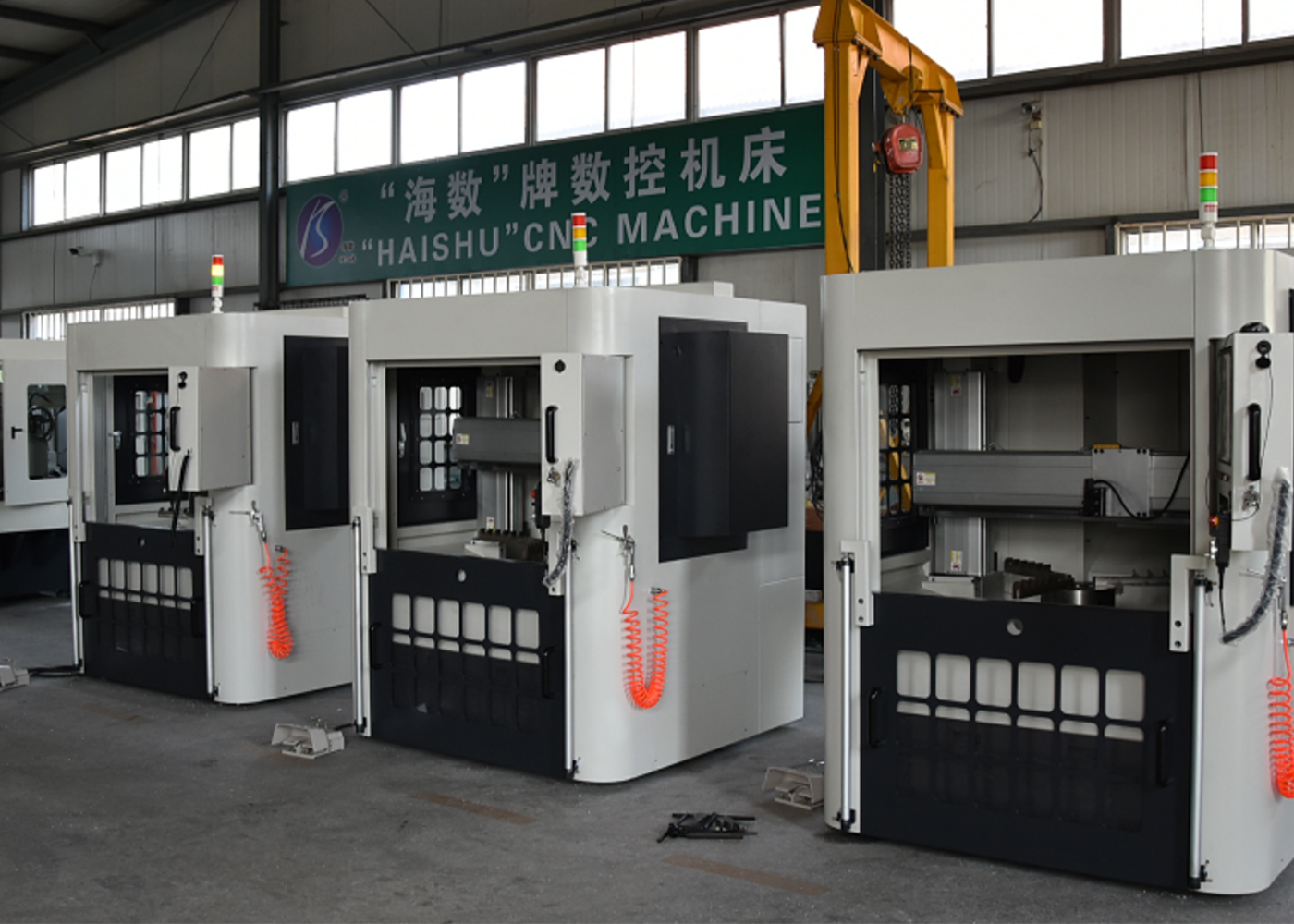

The mobile wheel repair lathe stands as a revolutionary advancement in the automotive repair industry, particularly catering to the urgent demands for quick and efficient on-site service. This compact yet powerful wheel repair machine is designed to bring the capabilities of a traditional workshop directly to the client’s location, ensuring both convenience and high-quality service.

What Are the Key Benefits of Using a Mobile Wheel Repair Lathe?

Portability and Power

Unlike the bulkier vertical wheel repair lathes, the Car Wheel Lathe features a lightweight design, making it easy to transport in standard vehicles like light trucks or sedans. This mobility allows technicians to provide services at a customer’s convenience without sacrificing the power needed for professional-grade wheel repairs.

Adaptable to Various Wheel Sizes

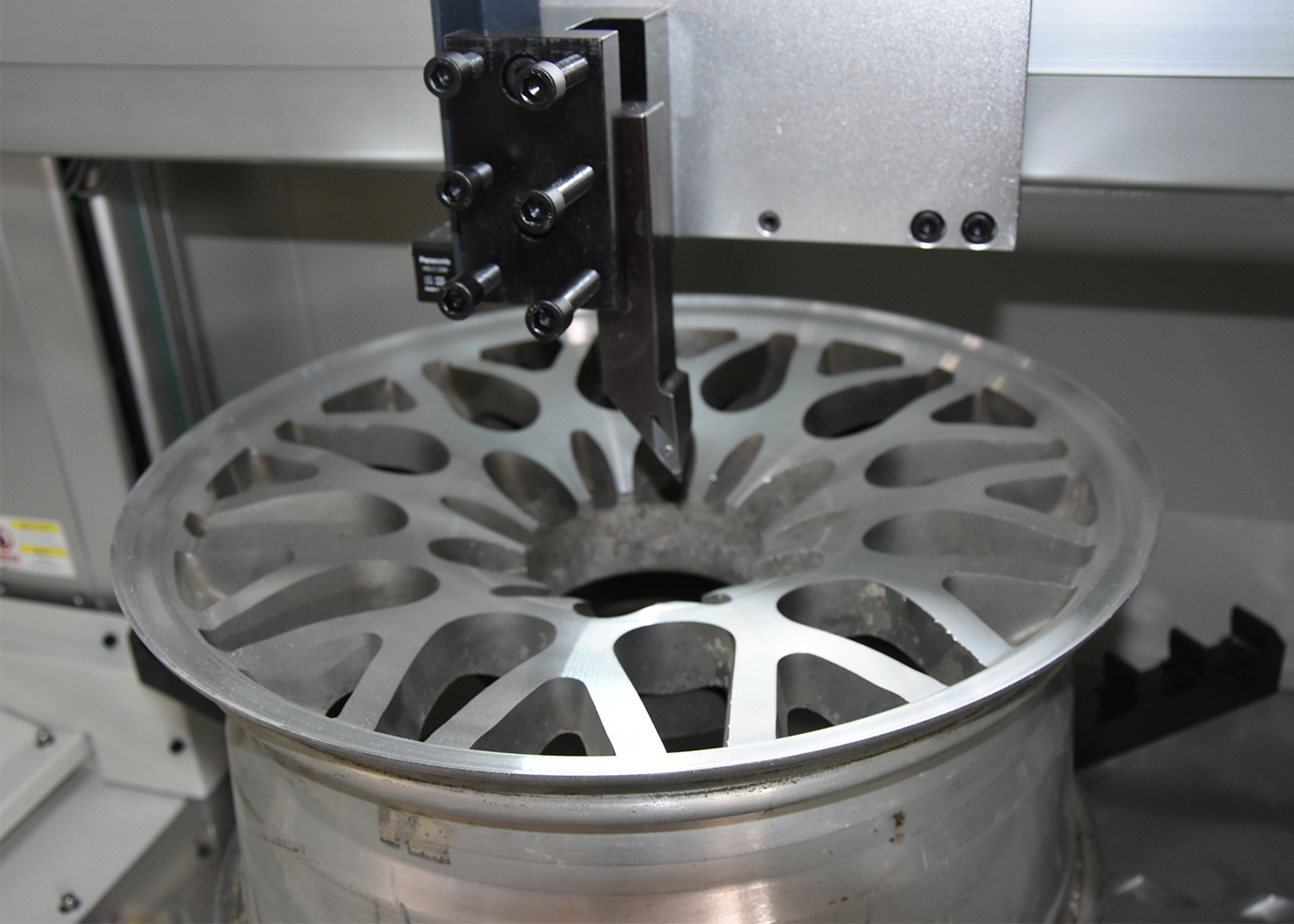

Thanks to its broad clamping range, this wheel CNC machine can accommodate a diverse array of wheel sizes. This adaptability makes it an invaluable tool for businesses that aim to service many different types of vehicles with speed and precision.

Efficiency on the Move

Equipped with features such as quick chuck clamping and rapid tool mounting, the wheel repair lathe significantly cuts down service time. This efficiency is crucial for handling multiple repair jobs within a tight schedule, making it an ideal solution for mobile operations.

Why Should Auto Repair Businesses Invest in a Mobile Wheel Repair Lathe?

Investing in a professional wheel repair lathe not only aligns with the growing trend toward mobile services but also enhances a business’s competitive edge. It meets the modern customer’s expectation for fast, reliable, and accessible service. Furthermore, by enabling on-site repairs, it supports environmentally friendly practices by reducing the need to replace parts unnecessarily.

How Does a Mobile Wheel Repair Lathe Maintain Quality and Precision?

Despite its compact size, the mobile wheel repair machine does not compromise on the quality of its repairs. The machine maintains high rigidity and precision, ensuring that even extensive wheel repairs meet the highest standards. This capability is essential for maintaining the safety and performance of vehicle wheels after repair.

What Makes the Mobile Wheel Repair Lathe Ideal for On-Site Operations?

Custom Power Options

Understanding the limitations at various service sites, especially where three-phase power may not be available, most mobile wheel repair lathes are equipped to operate on single-phase power (220V). This customization ensures that the machine can be used virtually anywhere, providing further flexibility for mobile services.

Streamlined Mobility Features

The design typically includes base wheels on the machine itself, allowing for easy movement within a vehicle or around a workshop. This mobility is crucial for professionals who need to quickly set up and start working without delay.

Conclusion: How Does the Mobile Wheel Repair Lathe Shape the Future of Automotive Services?

As the demand for efficient and flexible automotive services continues to grow, wheel repair equipment proves to be a crucial asset for service providers. It embodies the essence of modern convenience, merging portability with robust functionality, akin to a stationary wheel CNC machine. For auto repair businesses looking to expand their service offerings and adapt to the dynamic market needs, the rim repair machine offers a strategic advantage, ensuring that high-quality wheel repairs can be performed anytime and anywhere, in line with today’s mobile-first approach.

This technology not only elevates customer satisfaction through enhanced service delivery but also positions businesses at the forefront of the automotive service industry, promoting sustainable practices by extending the lifespan of vehicle wheels.