Alloy wheel repair is a meticulous process that restores damaged wheels to their original condition, ensuring both aesthetic appeal and vehicular safety. This service extends the life of the wheels and helps maintain the vehicle’s value.

How is Alloy Wheel Straightening Performed?

Wheel Straightening:

- Inspection: The wheel is detached and fixed onto a straightening device to ascertain any deformation.

- Heating for Flexibility: Heat is applied to the alloy to make it malleable, facilitating the reshaping process.

- Hydraulic Adjustment: Hydraulic tools are employed to correct the wheel’s form, reinstating its balance.

- Aluminum Welding: Any cracks or voids are filled using aluminum welding techniques.

- Precision Machining: The wheel undergoes fine-tuning through precision machining to ensure it meets original specifications.

What Does CNC Machining Involve in Alloy Wheel Repair?

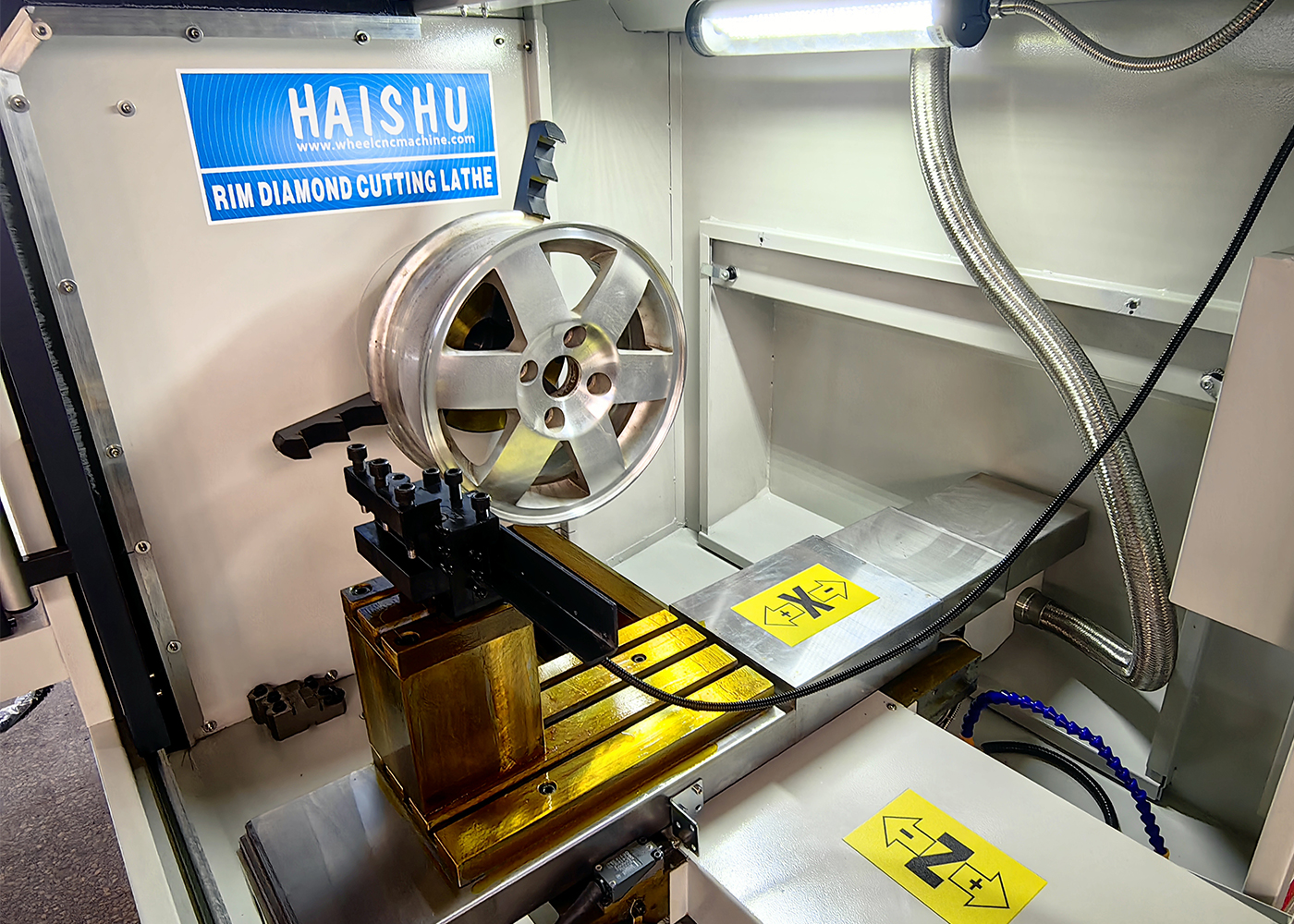

CNC Machining:

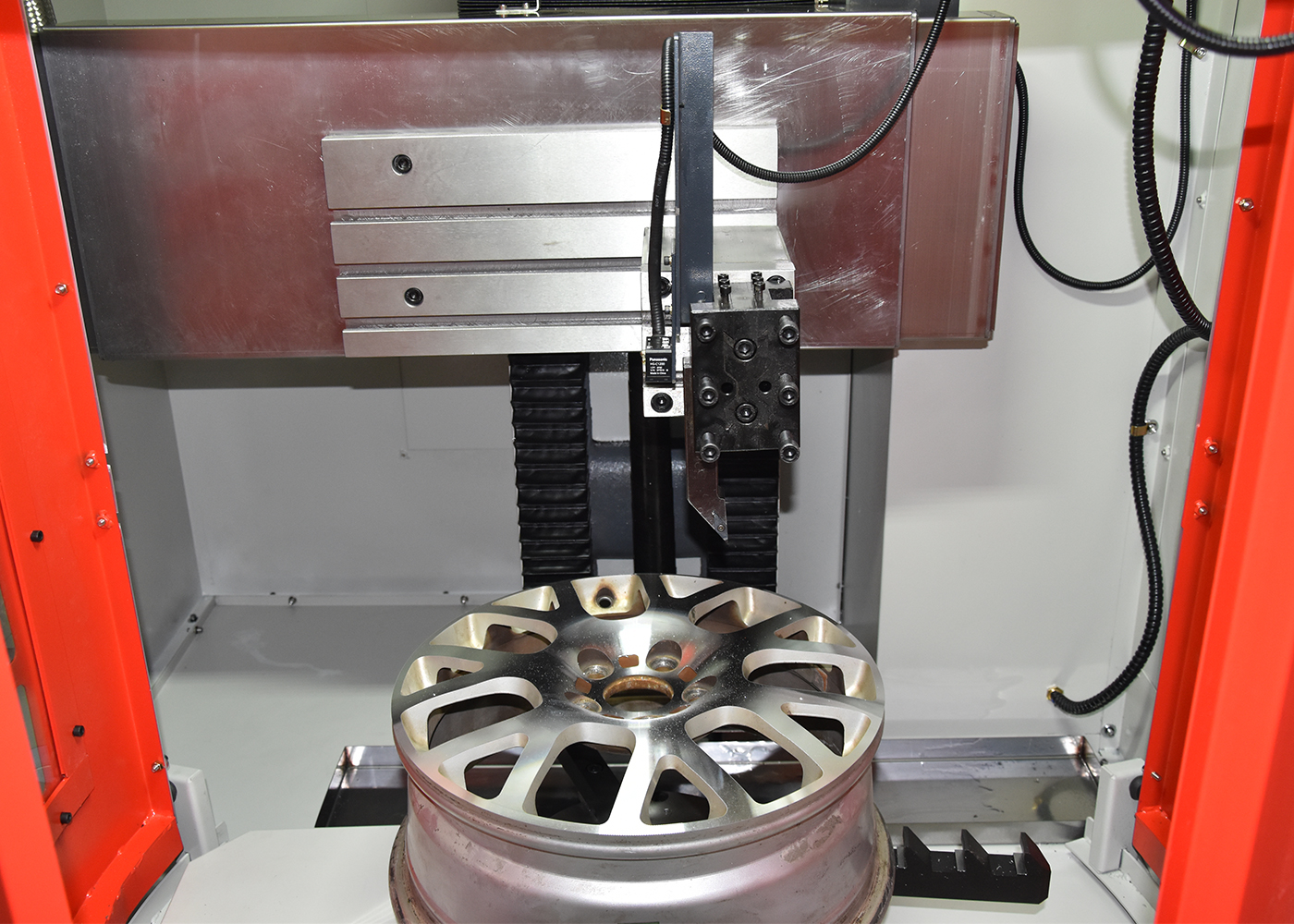

- Clamping and Detection: The wheel is secured and scanned with lasers or probes to determine its contour.

- Path Optimization: The machining path is optimized for efficiency, either automatically or with manual intervention.

- Programming: A CNC program is tailored to the specific wheel design.

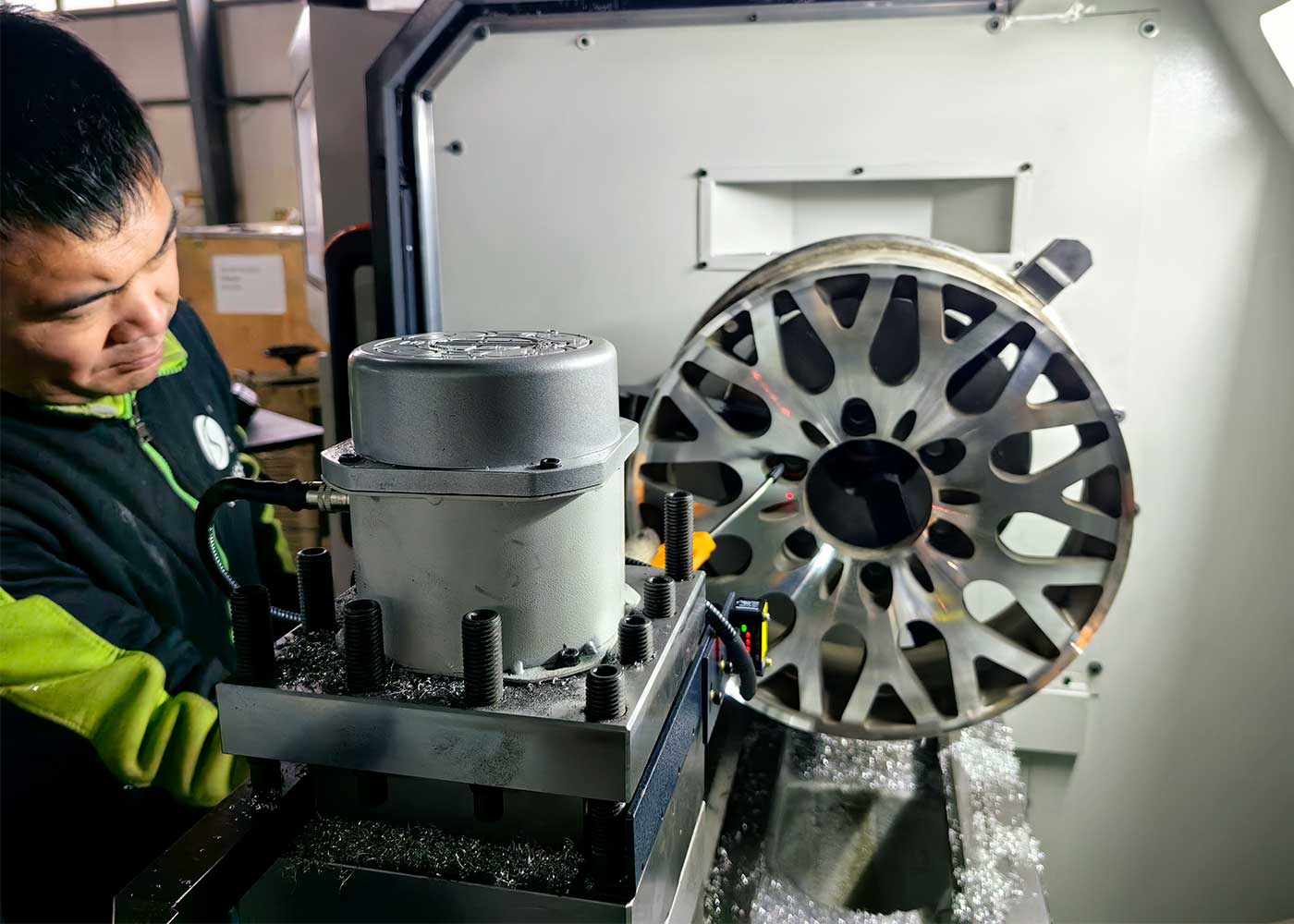

- Automated Cutting: The wheel is then shaped or cut with precision by a CNC machine.

- Surface Finishing: Final surface cleaning is conducted post-CNC cutting to prepare for coating.

What Finishing Touches Are Applied Post-Repair?

Surface Treatment:

- Specialized Cleaning: Post-machining, the wheel is treated with specific cleaning agents to remove any residues.

- Protective Coating: A protective lacquer is applied and the wheel is baked in an oven to set the finish.

- Reinstallation: Once the lacquer is cured, the wheel is ready to be mounted back onto the vehicle.

Minor Scratch Repair:

- For superficial scratches, a simpler process involving cleaning, electroplating, and curing is sufficient.

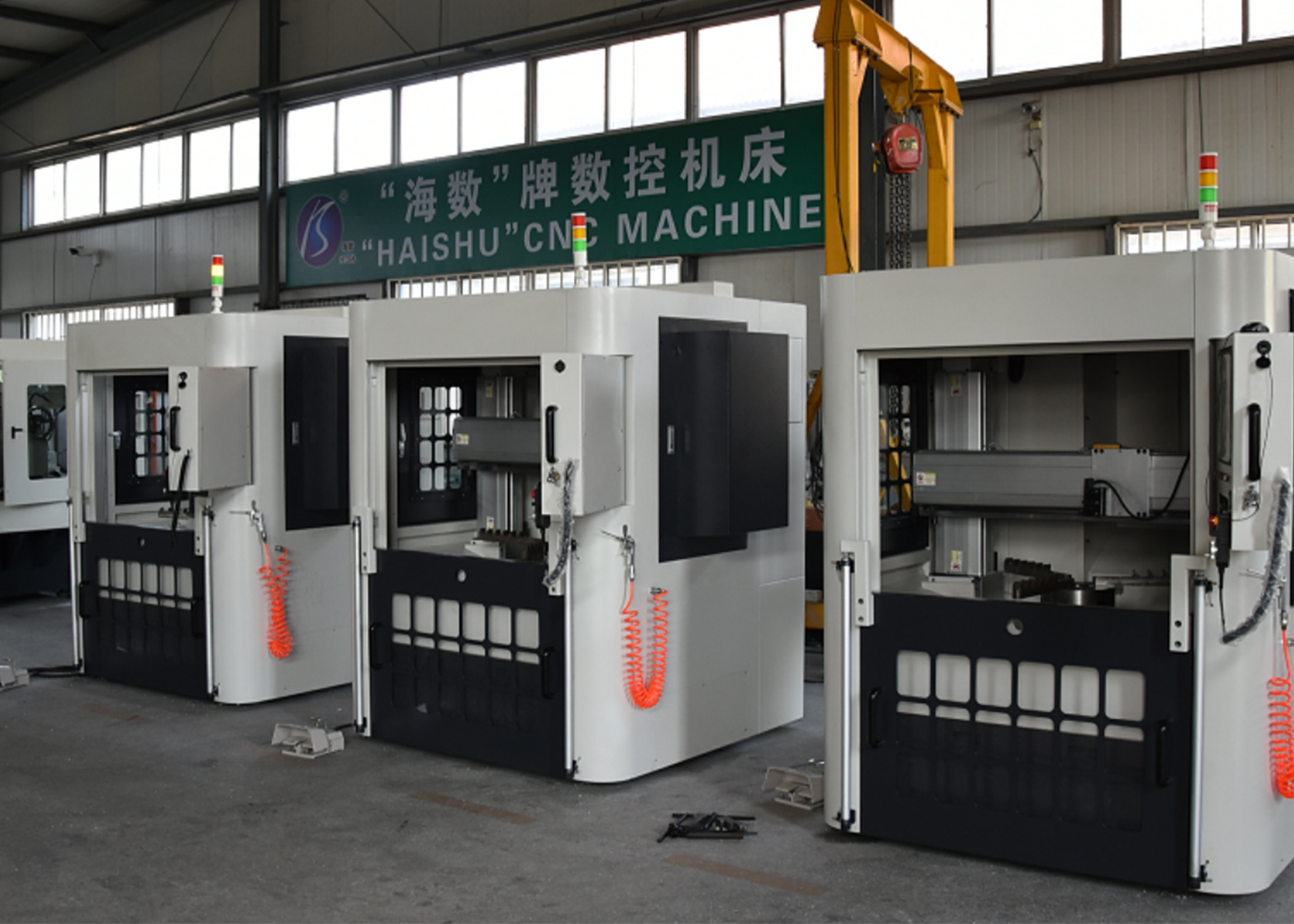

Why is HAISHU Machinery the Preferred Choice for Alloy Wheel Repair?

HAISHU’s equipment, specially designed for wheel repair, includes innovative wheel repair lathes, vertical wheel repair lathes, wheel repair machines, and wheel CNC machines. These are integral tools for executing high-quality alloy wheel repairs.

What Makes HAISHU Machinery Stand Out?

HAISHU’s machinery offers:

- State-of-the-Art Control: The advanced touchscreen system streamlines operations.

- Rapid Detection: The laser probe swiftly maps wheel geometry, speeding up the repair process.

- Efficient Optimization: The automatic curve optimization feature ensures the machining process is precise and efficient.

- User-Friendly Operation: Simplified one-button tooling and automatic machining features allow for ease of use even for novices.

- Connectivity Solutions: Networking capabilities enable remote management and access to instructional videos, enhancing support and maintenance.

HAISHU machinery’s cutting-edge technology ensures that every alloy wheel repair is performed with the highest level of accuracy and efficiency. The brand’s global presence, with a network of agents and accessibility in over 100 countries, including the USA, EU, Australia, and Asia, ensures comprehensive service and support.

How Can You Access HAISHU’s Alloy Wheel Repair Solutions?

How to Purchase or Represent HAISHU Machinery?

If you’re interested in acquiring HAISHU’s alloy wheel repair solutions or wish to become a distributor, the company offers straightforward avenues for both. Potential buyers and agents can reach out directly to HAISHU for more information, demonstrations, and pricing details. HAISHU’s commitment to customer service ensures that you receive personalized assistance throughout the purchase process and beyond.

From the innovative wheel repair lathe to the vertical wheel repair lathe and from the wheel CNC machine to the wheel repair machine, HAISHU’s product suite is designed to address every facet of the alloy wheel repair process. This commitment to excellence is why HAISHU stands as a leader in the wheel repair industry.

In summary, alloy wheel repair is not just about fixing cosmetic damage; it’s about returning the wheel to its original condition for safety and value retention. HAISHU Machinery’s advanced equipment and global support network make it an ideal partner for those seeking to deliver or receive top-tier wheel repair services. By choosing HAISHU, you ensure access to some of the most sophisticated wheel repair technologies available in the market today.