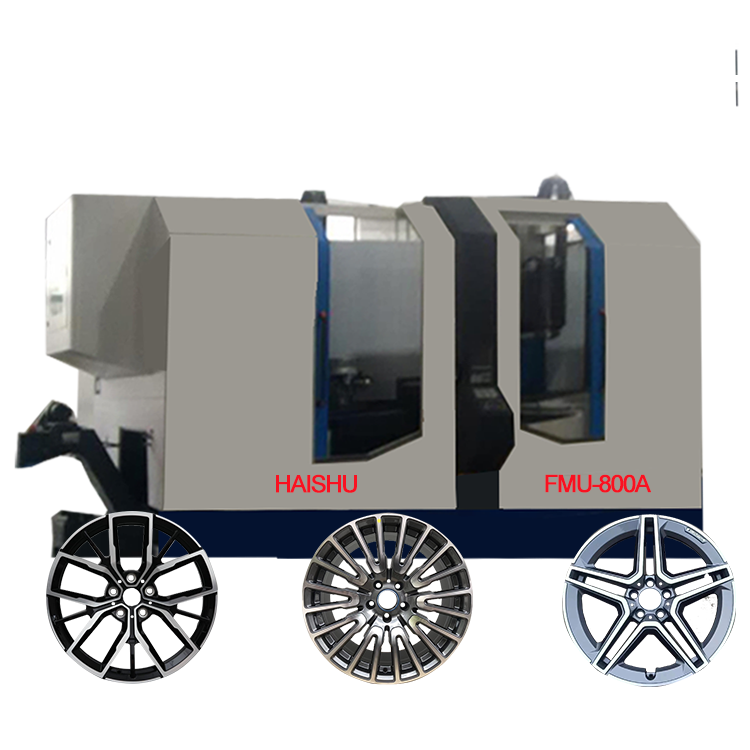

Customized CNC Vertical Wheel Machining Center

Description

Optimize Your Wheel Production with the Vertical Wheel Machining Center FMU-800A

Advanced Wheel CNC Machine for Impeccable Repairs

Haishu Machinery’s Vertical Wheel Machining Center FMU-800A is a testament to sophisticated design and manufacturing, tailored to meet specific technical demands. This wheel CNC machine is an indispensable asset for any automobile wheel factory seeking a blend of efficiency, precision, and customization.

Engineered for Excellence

Constructed from self-made mechanical components, including a cast steel bed, high-quality spindle, and precise fixing chuck, this wheel repair machine integrates seamlessly with the advanced GSK numerical control system. The robust feeding mechanism, paired with top-tier servo motors, ensures operations are smooth and reliable.

Streamlined Automation for Wheel Repair

The Vertical Wheel Machining Center is more than just a wheel repair lathe; it’s a complete solution equipped with a 24 tools library and a tool manipulator. The automatic tool changer, coupled with automatic loading, discharge, and chip removal, streamlines the wheel repair process, significantly reducing manual intervention.

A Hub of Wheel Production Efficiency

Positioned as a critical machine in the automatic wheel production line, this wheel CNC machine can be effortlessly connected with other CNC machines via a configured conveyor. This connectivity epitomizes a cost-effective, highly efficient, and flexible operation, making it a popular choice for wheel production and repair facilities worldwide.

The FMU-800A stands as a cornerstone of modern wheel repair and production, exemplifying the pinnacle of Vertical Wheel Machining Centers and setting the standard for the industry.

Customized CNC Vertical Wheel Machining Center FMU-800A

Customized Vertical Wheel Machining Center

2. Key Features of the Vertical Wheel Machining Center

Innovative Design and Functionality

Vertical, Double Spindle, and Dual-Position System

The Vertical Wheel Machining Center is ingeniously designed with a vertical orientation, incorporating double spindles and a dual-position layout to maximize productivity and space efficiency.

Advanced Tooling and Automation

Comprehensive Tooling System

This CNC wheel machining center boasts a 24-tool library, a tool manipulator, and an automated tool change system, enhancing the speed and precision of wheel manufacturing.

Automated Material Handling

With features for automatic loading, discharge, and chip removal, the machine streamlines the entire production process, reducing labor costs and increasing throughput.

Specialized Chuck and Tools

Equipped with a dedicated power chuck and specialized tooling, this CNC wheel machine caters to high precision requirements, ensuring each wheel is machined to exact specifications.

Expandable to a Full Production Line

By integrating a conveyor system, this Vertical Wheel Machining Center can form a complete, automated wheel production line, embodying the pinnacle of manufacturing efficiency.

Broad Machining Diameter Range

The machine’s wheel machining diameter range extends from 5 to 26 inches, accommodating a wide array of wheel sizes for diverse vehicle requirements.

High Precision and Customizable Setup

With its integrated design, modular manufacturing, and customizable installation, the Vertical Wheel Machining Center promises flexible operation. Its high precision and high configuration fulfill the most demanding machining needs, setting a new standard for automated wheel repair and production.

3. Technical Parameters of CNC Wheel Machining Center

| NO. | ITEM | UNIT | Parameters |

| Vertical Wheel Machining Center Table | |||

| 1 | Table size | mm | 800 |

| 2 | Spindle speed | rpm | 6500 |

| 3 | Max. load on table | kg | 500 |

| 4 | Distance from floor to table top | mm | 700 |

| Machining Capacity | |||

| 5 | X-axis Movement | mm | 800 |

| 6 | Y-axis Movement | mm | 150 |

| 7 | Z-axis Movement | mm | 400 |

| 8 | Distance from spindle face to table top | mm | 500 |

| 9 | Distance from spindle center to column guideways | mm | 300 |

| 10 | Coolant supply – Flood coolant around the spindle | lpm | 50 |

| Spindle parameters | |||

| 11 | Spindle nose tapper | BT | 7/24 No. 30 |

| 12 | Spindle speed | rpm | 80-8000 |

| 13 | Spindle speed – Std. direct drive (D.D) | rpm | 60-6000 |

| 14 | Spindle bearing diameter – Opt. indirect drive (D.D) | mm | 70 |

| 15 | Tool clamping force | Kgf | 450 |

| Feed parameters | |||

| 16 | Rapid traverse X/Y/Z | m/min | 30/30/30 |

| 17 | Cutting feed | mm | 1-10000 |

| 18 | Ball screw diameter for X/Y/Z | mm | 35/45/45 |

| 19 | Guideways for X/Y/Z | Linear | |

| Automatic tool changer | |||

| 20 | Number of tools | 24 | |

| 21 | Max. tool diameter | mm | 60 |

| 22 | Max. tool diameter with adjacent pocket empty | mm | 155 |

| 23 | Tool to tool time | sec | 1.4 |

| 24 | Max. tool height | mm | 200 |

| 25 | Max. tool weight | Kg | 15 |

| Accuracy with rotary encoder | |||

| 26 | Positioning for X,Y, Z & Z axis as per JIS B6330 | mm | 0.005 |

| 27 | Repositioning for X,Y, Z & Z axis as per JIS B6330 | mm | ±0.003 |

| Motors | |||

| 28 | Spindle motor 15/30 min/cont (GSK) | Kw | 7.5/5.5 |

| 29 | Feed motor for X,Y, Z axis (GSK) (Y Axis optional) | Nm | 10/10/10 |

| Installation data | |||

| 30 | Wheel machining center width | mm | 2500 |

| 31 | Wheel machining center height | mm | 1100 |

| 32 | Wheel machining center depth | mm | 1950 |

| 33 | Wheel machining center weight – net | Kg | 8400 |

| 34 | CNC control (7.2 ” monochrome LCD / 10.4″ color LCD) | GSK988 (Optional) | |

| Tank capacity | |||

| 35 | Coolant tank | litre | 300 |

| 36 | Lubrication tank (useful quantity) | litre | 5 (4) |

| Machine features / accessories -standard | |||

| 37 | Panel cooler for electronics (Optional) | ||

| 38 | Counter Balancing for Z axis | ||

| 39 | Fall safe break for Z axis | ||

| 40 | Flexible coupling for X, Y, Z axis | ||

| 41 | Standard work light | ||

| 42 | Manual – 1 set | ||

| 43 | Manual pulse generator (Optional) | ||

| 44 | Rapid tapping | ||

| 45 | Total machine enclose | ||

| 46 | Coolant tank & chip tray | ||

| 47 | X; Z; CS1; CS2 (Optional) | ||

| 48 | Chip disposal to the rear side | ||

Expand Your Capabilities with Optional Components

Tailor Your Vertical Wheel Machining Center

Our CNC vertical wheel machining center can be customized with a variety of optional components to meet your specific production needs. Enhance your machining capabilities and adapt to a range of requirements with these add-ons:

Milling Spindle for Versatile Machining

Upgrade your machine with an additional milling spindle, allowing for more complex and varied machining tasks, including drilling, tapping, and more intricate milling operations.

Specialized Wheel Power Chuck

Opt for a wheel-dedicated power chuck to ensure superior grip and precision handling of wheels during the machining process, leading to improved accuracy and finish.

Advanced Tooling Options

Extensive Tool Library

Expand your tooling options with an extended tool library, providing immediate access to a variety of tools and facilitating quick changeovers for diverse machining needs.

CNC Tool Handler

Integrate a CNC tool handler to automate tool changes, reducing downtime and increasing efficiency in your production line.

Enhanced Milling and Grinding Capabilities

Multi-Angle Milling Head

Increase flexibility with a multi-angle milling head, allowing for the execution of complex milling paths and angles without the need for repositioning the workpiece.

CNC Grinding Head

Incorporate a CNC grinding head to perform precision grinding tasks, vital for creating smooth and finely finished surfaces on your machined wheels.

Customize to Your Needs

Remember, you can propose your special requirements to us. Whether you need enhanced precision, flexibility, or efficiency, we can help you configure your Vertical Wheel Machining Center with the right optional components to elevate your production capabilities.

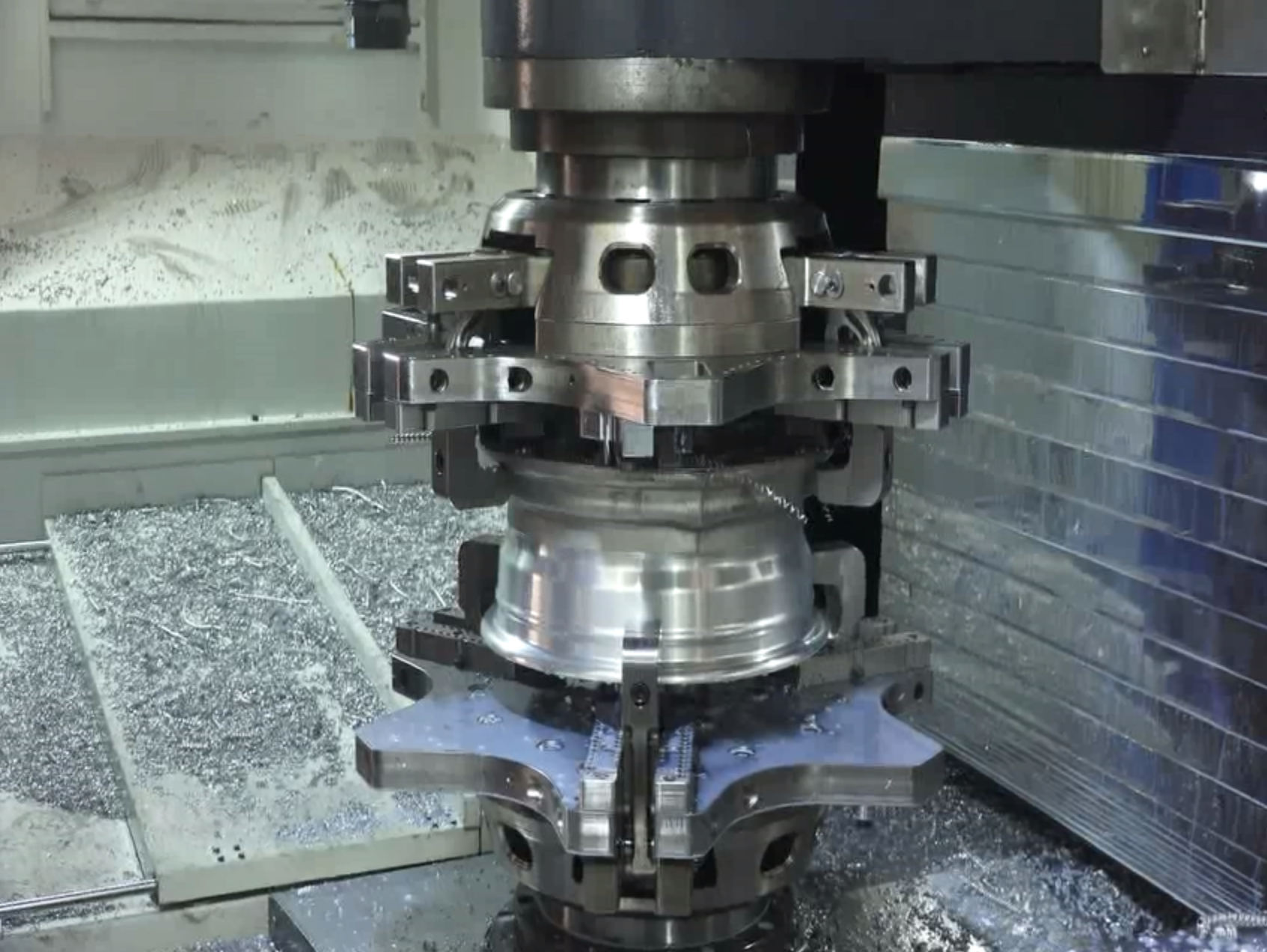

Fig. 2 Customized CNC Vertical Wheel Machining Center parts

Fig. 2 Customized CNC Vertical Wheel Machining Center parts

Introducing Taian Haishu Machinery Co., Ltd.

Driving Innovation in CNC Wheel Machining Solutions

Since its inception in 2001, Taian Haishu Machinery Co., Ltd. has established itself as a foremost designer and manufacturer of specialized CNC machinery, catering to the global automobile wheel production and repair industry. Our commitment to innovation and leadership in CNC lathe technology has been the cornerstone of our operations for over two decades.

A Commitment to Excellence and Growth

Our expansive 12,000-square-meter facility is home to a dedicated team of over 30 experts, where we harness our passion for innovation, simplicity, and efficiency. From the beginning, our focus has been on advancing CNC software, optimizing structural design, refining process planning, scaling manufacturing, and ensuring rigorous quality control.

A Spectrum of High-Quality CNC Solutions

Our product lineup is both varied and specialized, featuring:

- Wheel CNC Machine

- Wheel Repair Machine

- Brake Drum Lathe

- Customized CNC Solutions

We also offer precision machines tailored to alloy wheel repair and maintenance, including:

- Alloy Wheel CNC Lathe

- Wheel Straightening Machine

- Alloy Wheel Polishing Machine

- Rim Straightening Machine

- Brake Disc Lathe

Our innovative machinery solutions serve a diverse and international clientele, spanning continents from Germany to South Korea, and industries from automotive repair to specialized CNC applications.

Global Reach, Local Partnership

Haishu Machinery’s reputation for quality has made us the preferred partner for clients in over 30 countries, including emerging and established markets such as Germany, Russia, Spain, India, and many more. We pride ourselves on the trust and satisfaction our clients place in our machinery.

Join Our Global Network

As we continue to expand our global footprint, we are actively seeking partnerships worldwide. At Haishu Machinery, we’re not just building machines; we’re forging enduring relationships and driving the future of CNC machining technology. Join us in our journey to redefine precision and efficiency in the automobile wheel industry.