Vertical Wheel Repair Lathe: Revolutionizing Wheel Refurbishment

Introduction to Vertical Wheel Repair Lathe Technology

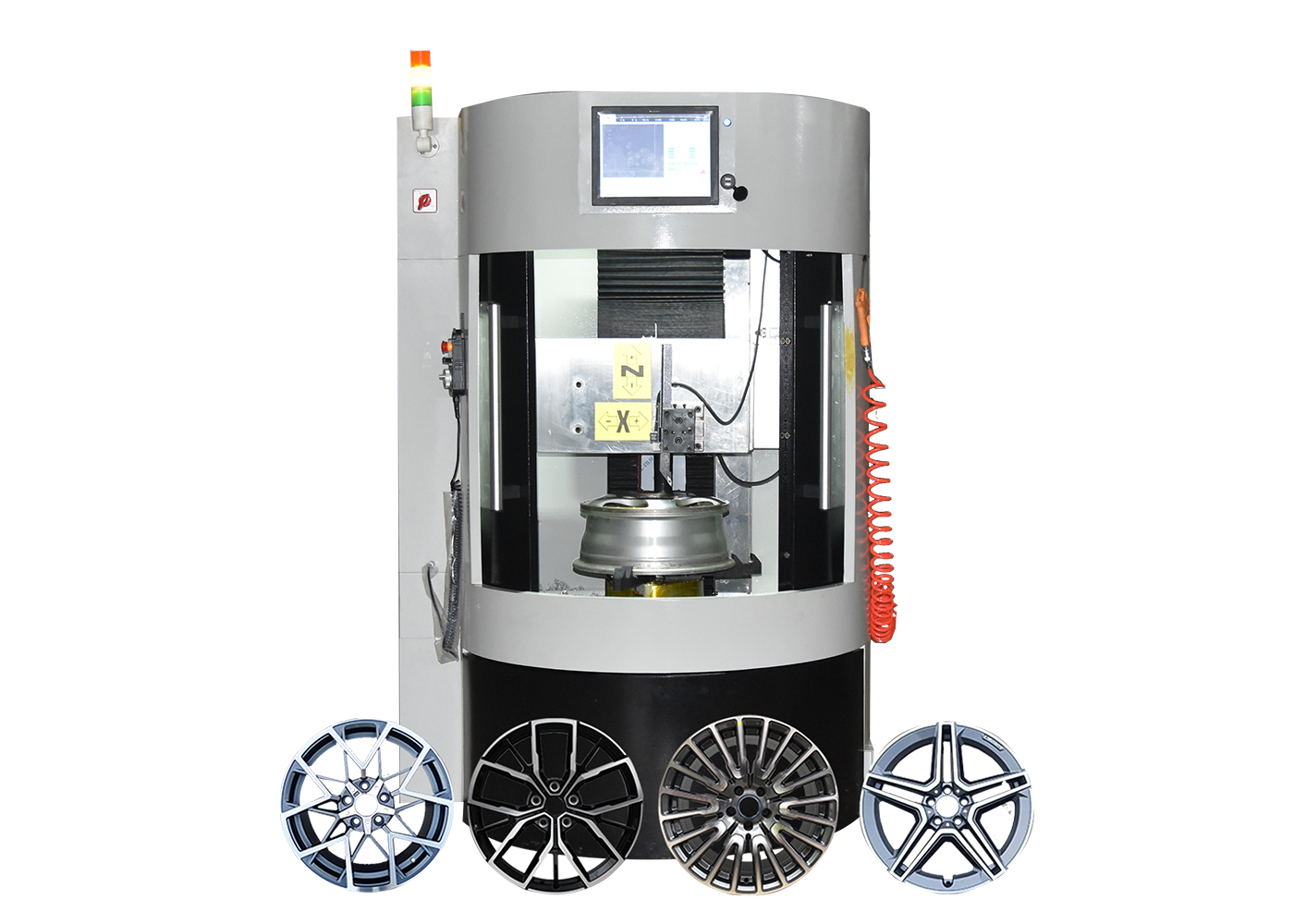

The Vertical Wheel Repair Lathe stands as a paradigm shift in the realm of wheel refurbishment. Unlike traditional horizontal lathes, this innovative Wheel CNC Machine opts for a vertical orientation, where the spindle stands perpendicular to the ground. This strategic arrangement not only ensures a compact footprint ideal for space-constrained garages and small shops but also offers enhanced precision and user convenience.

Compact Design: The Space-Saving Solution

With a vertical structure, the Vertical Wheel Repair Lathe boasts unrivaled space efficiency. This Compact Wheel Refinishing Machine is a perfect fit for garages, automotive shops, and small retail outlets where space comes at a premium.

User-Friendly Operation: Convenience Meets Efficiency

The ease of operation is another hallmark of the Vertical Wheel Repair Lathe. Its horizontal wheel mounting system significantly reduces the strain of lifting and clamping heavy wheel hubs, streamlining the workflow in repair shops. This feature makes it an invaluable Rim Repair Equipment for technicians who prioritize ergonomic work conditions.

Precision Machining: The Heart of Wheel Refurbishment

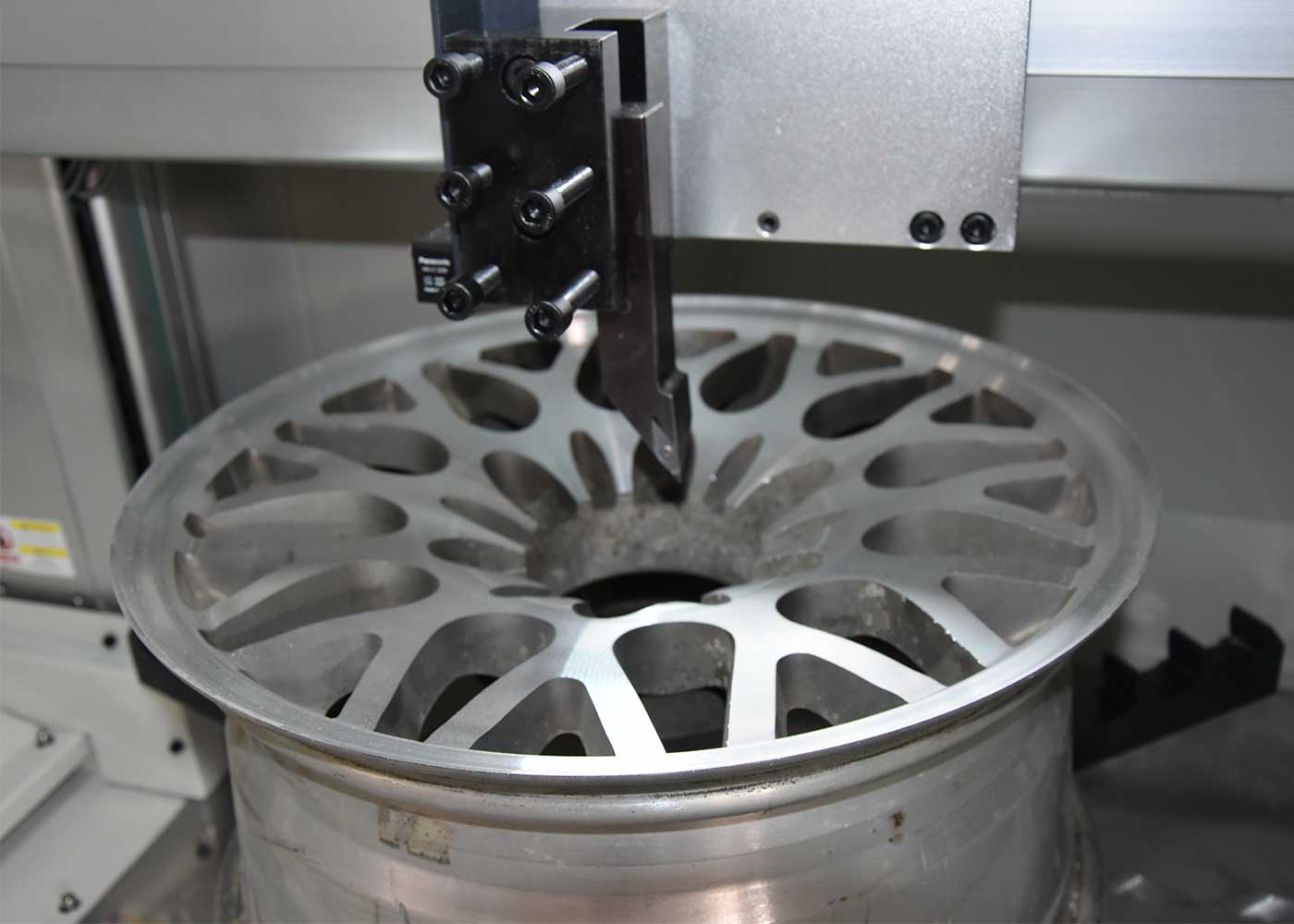

Precision is the cornerstone of any Wheel Restoration Machine, and the Vertical Wheel Repair Lathe delivers with its robust design and linear guides. These features ensure that the Alloy Wheel Repair Machine performs with minimal error, providing a precise finish for every wheel.

Superior Chip Management: Keeping the Workspace Clean

A standout feature of the Vertical Wheel Repair Lathe is its superior chip removal capability. This design intuitively allows chips to fall away from the work area, maintaining a clean environment and preventing potential damage to the wheel or machine.

Advantages Of Horizontal Wheel Repair Lathes

Horizontal lathes have been the industry standard for years, known for their broad applicability and stable machining platform. However, when it comes to wheel repair, the Vertical Wheel Repair Lathe offers a more specialized approach. The vertical configuration provides better rigidity and is often more compact, making it the preferred Rim Refurbishment Machine for small-scale operations.

Automation and Versatility

Despite the compact size of the Vertical Wheel Repair Lathe, it does not fall short of versatility. Many models, such as the Automated Wheel Repair Machine and Alloy Wheel Diamond Cutting Machine, are compatible with automation, streamlining the wheel repair process even further.

Delving Deeper: The Multifaceted Functions of Vertical Wheel Repair Lathes

Vertical wheel repair lathes are not just about correcting imperfections; they are comprehensive Wheel Polishing Machines and Rim Straightening Machines. From removing deformations to ensuring balance and cleaning wheel hubs, these machines are equipped to handle all aspects of wheel repair.

Specialized Machining for Unique Wheels

For more specialized requirements, such as unique alloy compositions or intricate rim designs, the Vertical Wheel Repair Lathe can be configured as a Mobile Wheel Repair Lathe or a Diamond Cutting Wheel Lathe to provide precise and custom-tailored wheel machining services.

Applications Across the Automotive Sector

The scope of a Vertical Wheel Repair Lathe extends to various sectors. From the automotive repair industry to public transportation maintenance, these machines are pivotal in ensuring the integrity and safety of wheel hubs across a myriad of vehicles.

Key Industry Applications

- Automotive Repair Industry: Auto repair shops heavily rely on the Alloy Wheel Lathe for day-to-day operations.

- Public Transportation Systems: Maintenance hubs use these machines to service buses and trains.

- Specialty Vehicle Maintenance: Military and construction vehicles benefit from the heavy-duty capabilities of the CNC Wheel Lathe.

- Wheel Hub Remanufacturing: The Wheel Refinishing Machine plays a critical role in bringing old wheel hubs back to life.

Design Features That Define Excellence

A Vertical Wheel Repair Lathe is not just about functionality but also about design excellence. Every aspect, from the Precision Linear Guide Configuration to the Arc Sheet Metal Design, is meticulously crafted to enhance performance, safety, and aesthetics.

Enhancing Operation Through Design

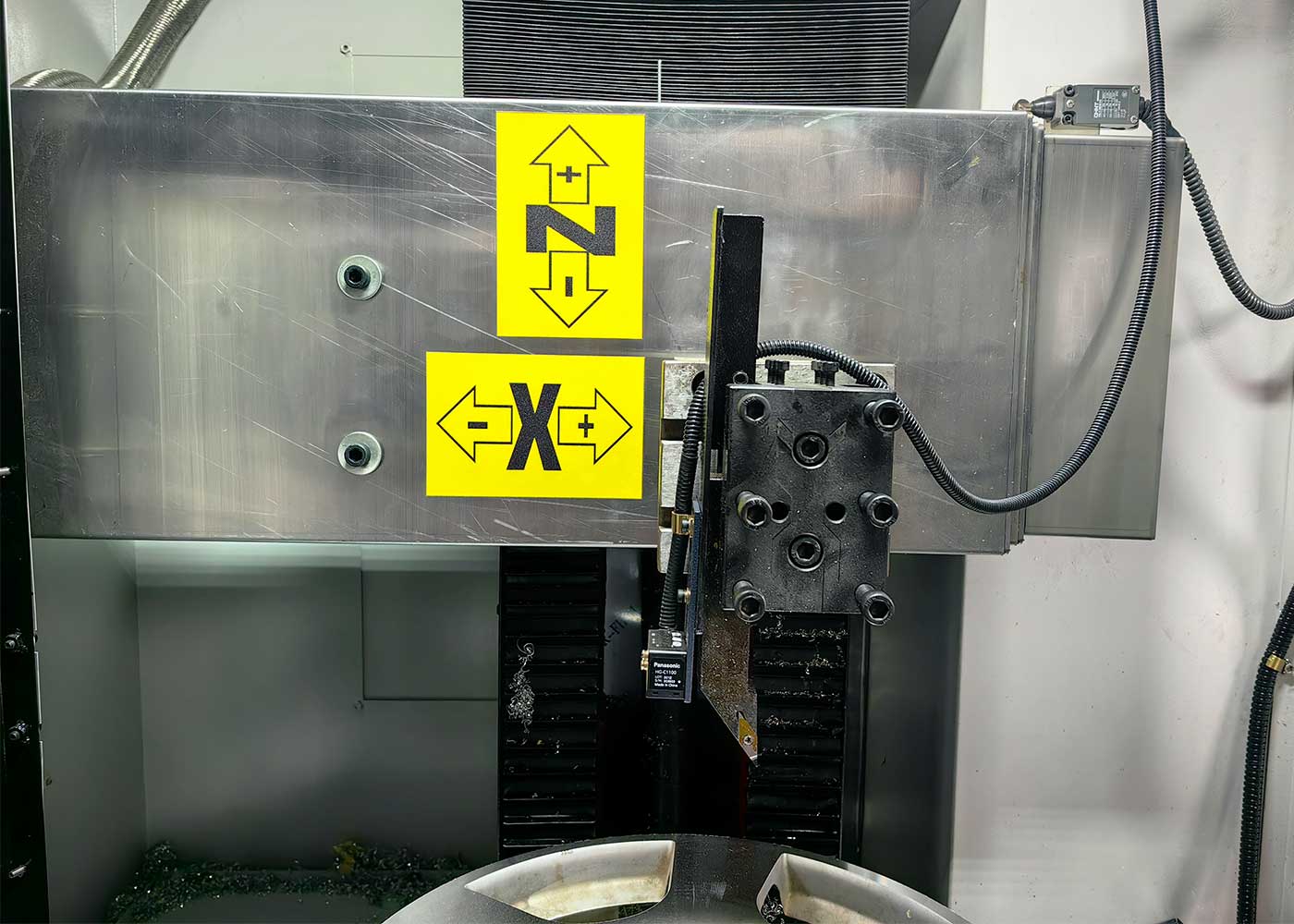

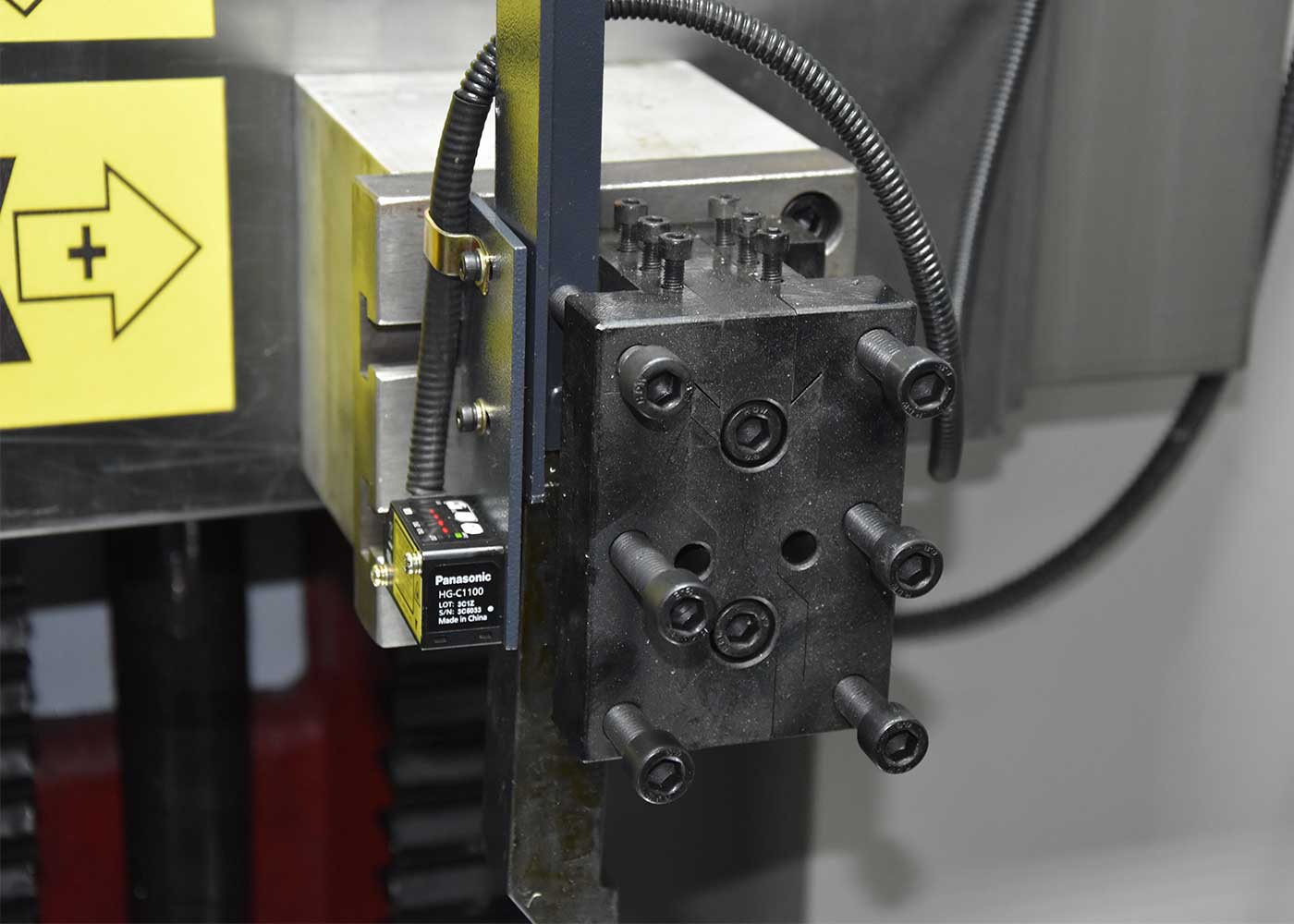

The Rim Refurbishment Machine is designed to enhance the operator’s experience, with features such as a Straight Line Tool Post for quick tool changes and a Cast Iron Base for vibration absorption. These attributes make the Wheel Repair CNC Lathe not only a powerhouse of efficiency but also a pinnacle of design ingenuity.

Conclusion: The Future Is Vertical

The Vertical Wheel Repair Lathe is more than just a machine; it’s a comprehensive solution for wheel repair and refurbishment. With its compact size, ease of use, precision, and superior chip removal, it represents a significant advancement in wheel repair technology. Whether you’re in the market for an Alloy Wheel Repair Machine markdown

Discover the Efficiency of Vertical Wheel Repair Lathes

Revolutionize Rim Refurbishment with HAISHU’s CNC Wheel Lathe

Automotive repair centers constantly seek to enhance their service quality, especially when dealing with the delicate task of wheel hub refurbishment. HAISHU’s CNC Wheel Lathe emerges as a frontrunner, offering state-of-the-art rim repair equipment that integrates seamlessly into any repair service setup.

The Technical Edge of HAISHU’s Alloy Wheel Repair Machine

The HAISHU CKL22Q Alloy Wheel Repair Machine boasts an impressive suite of technical specifications. It handles a maximum processing size of 26 inches, covering almost all wheel sizes in the market. With a powerful 15Nm torque motor and a sturdy cast iron base, it provides both strength and stability, which are essential for precision work on alloy wheels.

Clamping wheels horizontally, this machine eliminates issues from centrifugal forces, ensuring a swift and precise setup. Its CNC system not only optimizes data for machining but also enables a one-touch tool setting for automatic operations. The X-axis and Z-axis travel of 380mm and ±310mm respectively allow for accommodating various rim sizes with ease, making this Alloy Wheel Lathe a versatile and indispensable tool.

Enhancing Rim Repair Efficiency with the Vertical Wheel Repair Lathe

The Vertical Wheel Repair Lathe stands out by speeding up wheel hub repairs and minimizing downtime. With quick clamping and positioning, the HAISHU CKL22Q elevates work efficiency and throughput. Its ergonomic design and increased safety measures, like a fully enclosed protection shield, make it a preferred choice for professional rim refurbishment services.

Precision and Quality with Rim Repair Equipment

High-precision linear guides and a straight-line tool post offer unmatched accuracy, ensuring that every wheel that leaves the shop is as good as new. HAISHU’s Rim Repair Equipment is designed for ease of operation and maintenance, which is critical for busy automotive repair centers aiming for high-quality wheel polishing and refinishing.

The HAISHU Difference in Wheel Polishing and Refinishing

With HAISHU’s Wheel Polishing Machine, businesses can promise their clients near-factory condition restoration. The high-speed cutting and automated features reduce the need for manual intervention, ensuring a consistent and high-quality finish.

Case Study: Enhancing Automotive Repair with the Rim Refurbishment Machine

A luxury vehicle service center upgraded to HAISHU’s Rim Refurbishment Machine and experienced a surge in efficiency and customer satisfaction. The vertical design allowed for quick assessment and resolution of issues, leading to shorter wait times and a significant increase in repeat business.

Conclusion: Elevate Your Service with HAISHU’s Wheel Refinishing Machine

The HAISHU Vertical Wheel Repair Lathe is an investment in quality, efficiency, and safety for automotive repair services. With its advanced CNC system and robust construction, it stands as a pillar of modern rim repair and wheel refinishing.

Get the Best in Wheel Hub Restoration with HAISHU Machinery

For unparalleled wheel hub repairs and restorations, choose HAISHU Machinery’s precision lathes. Embrace the power of automation and precision with our Alloy Wheel Lathe and witness your business thrive. Visit our website or contact our hotline for a transformative approach to wheel repair. With HAISHU, aim for excellence in every restoration.