What Is Wheel Drawing Repair?

Wheel drawing repair is a specialized process used to repair and enhance the aesthetic appeal of various types of wheels. This technique involves grinding the surface of the wheel to create intricate lines and patterns, transforming the wheel into a more attractive, three-dimensional, and personalized component. The primary goal of Alloy wheel lathe is not just to restore the wheel but to elevate its visual appeal, giving it a unique and custom look that stands out.

How Does Wheel Repair Lathe Contribute to Wheel Drawing Repair?

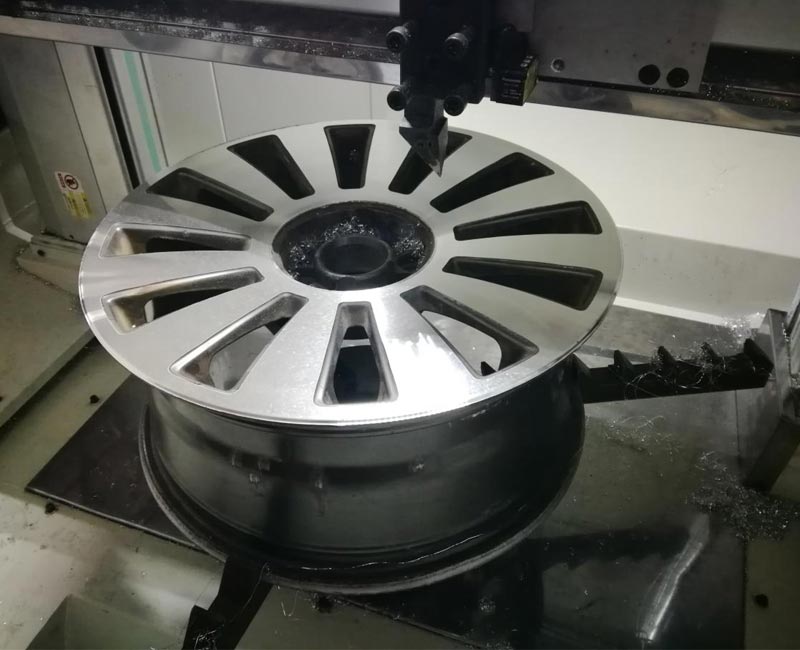

A wheel repair lathe is an essential tool in the Rim repair lathe process. It is specifically designed to address and fix damages such as scratches, dents, and other imperfections on the wheel’s surface. By using a vertical wheel repair lathe, technicians can ensure that the base surface is perfectly smooth and ready for the drawing process. This preparation is crucial as it significantly affects the final outcome, enhancing the wheel’s durability and extending its lifespan. The use of a wheel repair machine helps in minimizing wastage by refurbishing damaged wheels that would otherwise be discarded.

Why Are Wheel CNC Machines and Wheel Refurbishment Machines Important in Wheel Drawing Repair?

Wheel CNC machines play a pivotal role in the Wheel CNC lathe process. These machines provide high precision and control, which are essential for implementing detailed and consistent designs on the wheel’s surface. The CNC technology allows for the exact replication of desired patterns, ensuring each wheel is refurbished to meet specific aesthetic standards.

Similarly, wheel refurbishment machines are integral to achieving a high-quality finish. After the initial reshaping and repair done by the wheel repair lathe, the wheel refurbishment machine takes over to perform the final drawing and finishing touches. It ensures that the decorative lines are neatly engraved, and the wheel surface is polished to highlight the metallic texture, enhancing its overall look and feel.

The combination of wheel repair lathes, wheel CNC machines, and wheel refurbishment machines in wheel drawing repair not only revitalizes the appearance of the wheels but also contributes to their functionality and longevity. These tools allow for a level of customization that appeals to vehicle owners looking for a unique or bespoke aesthetic for their cars. Brushed finishes, achieved through these processes, offer a visually appealing dual-color effect that adds depth and a luxurious feel to the wheels.

In conclusion, wheel drawing repair is more than just a repair job; it’s an upgrade for your vehicle’s wheels. Utilizing advanced tools like wheel repair lathes, wheel CNC machines, and wheel refurbishment machines ensures that each wheel is not only restored to its original condition but is also enhanced to become a statement piece of the vehicle. As the popularity of custom wheel designs grows, the technology and techniques for Alloy wheel refurbishing lathe continue to evolve, promising even more exciting possibilities for car enthusiasts worldwide.