Efficient Alloy Wheel Polishing Machine

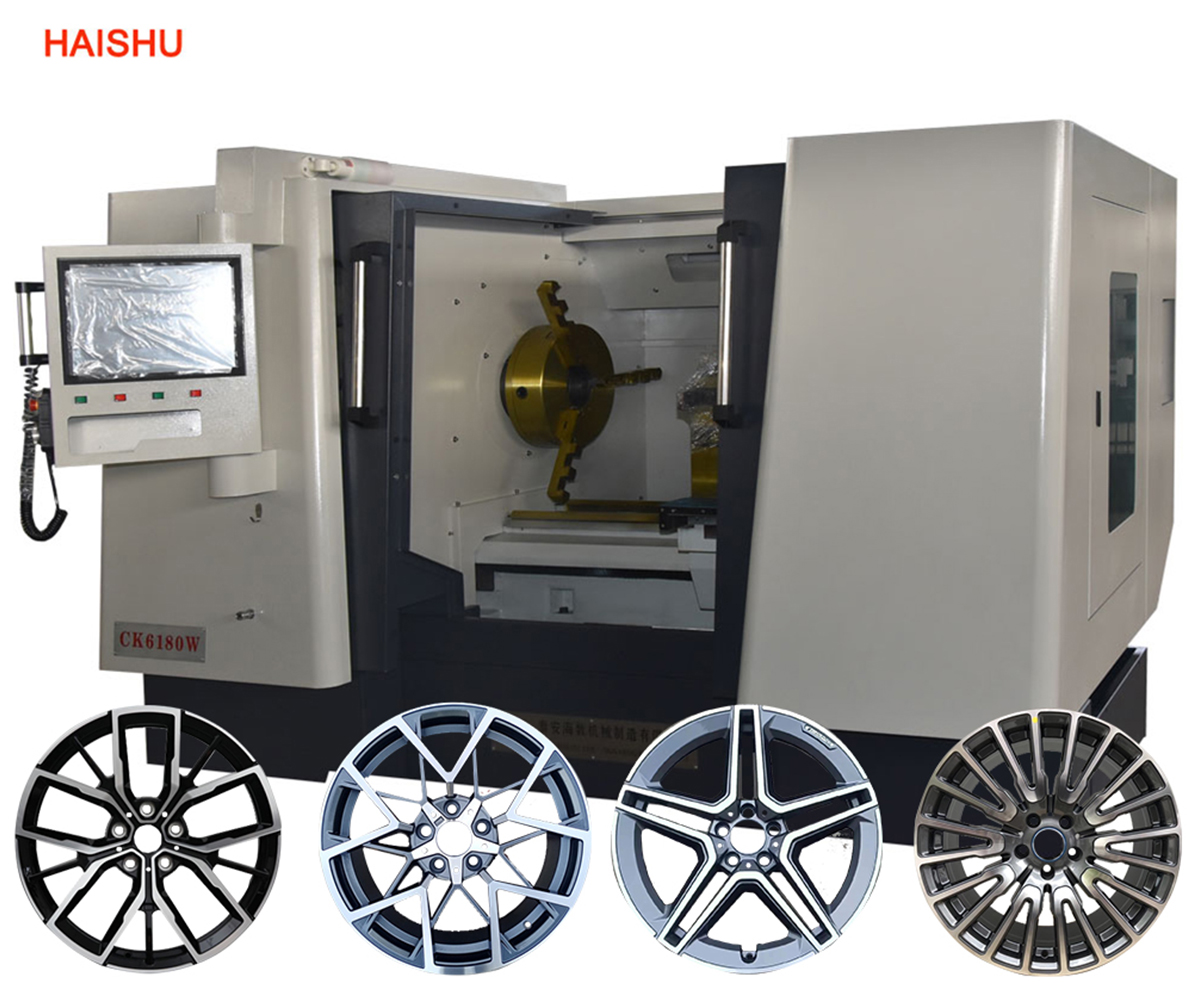

The Alloy Wheel Polishing Machine (also known as a wheel repair lathe or wheel refurbishment machine) is extensively utilized for repairing various types of wheels and tools. Haishu Machinery has designed and manufactured the highly efficient and cost-effective Alloy Wheel Polishing Machine K6180W, which is also space-saving. This machine is primarily targeted towards automobile wheel production factories and repair shops.

One of our long-term customers expressed the need for a new type of alloy wheel polishing machine equipped with a touch screen system. Once the customer confirmed the workpiece processing size, they reviewed the operating video of our new machine and decided on the appropriate model. Having developed a strong trust in our product quality over time, the customer promptly arranged the payment.

Our Alloy Wheel Polishing Machine K6180W is designed to meet the highest industry standards in terms of efficiency, precision, and ease of operation. With its touch screen system, it offers a user-friendly interface that simplifies the polishing process. The machine is equipped with advanced technology and reliable components to ensure optimal performance and long-lasting durability.

At Haishu Machinery, we continually strive to exceed customer expectations by delivering top-quality machines. Our alloy wheel polishing machines have gained a reputation for their reliability, effectiveness, and cost-efficiency. We are dedicated to providing excellent service and support to our customers, enabling them to enhance their wheel repair and refurbishment operations.

As the professional Wheel CNC Machine Manufacturer, we have over 17 years of experience in development, production and exporting Wheel repair lathe, Wheel Repair Machine and Drum brake lathe, and our products have been sold well to over 50 countries. Our company has passed the ISO9001 quality system and CE certification.

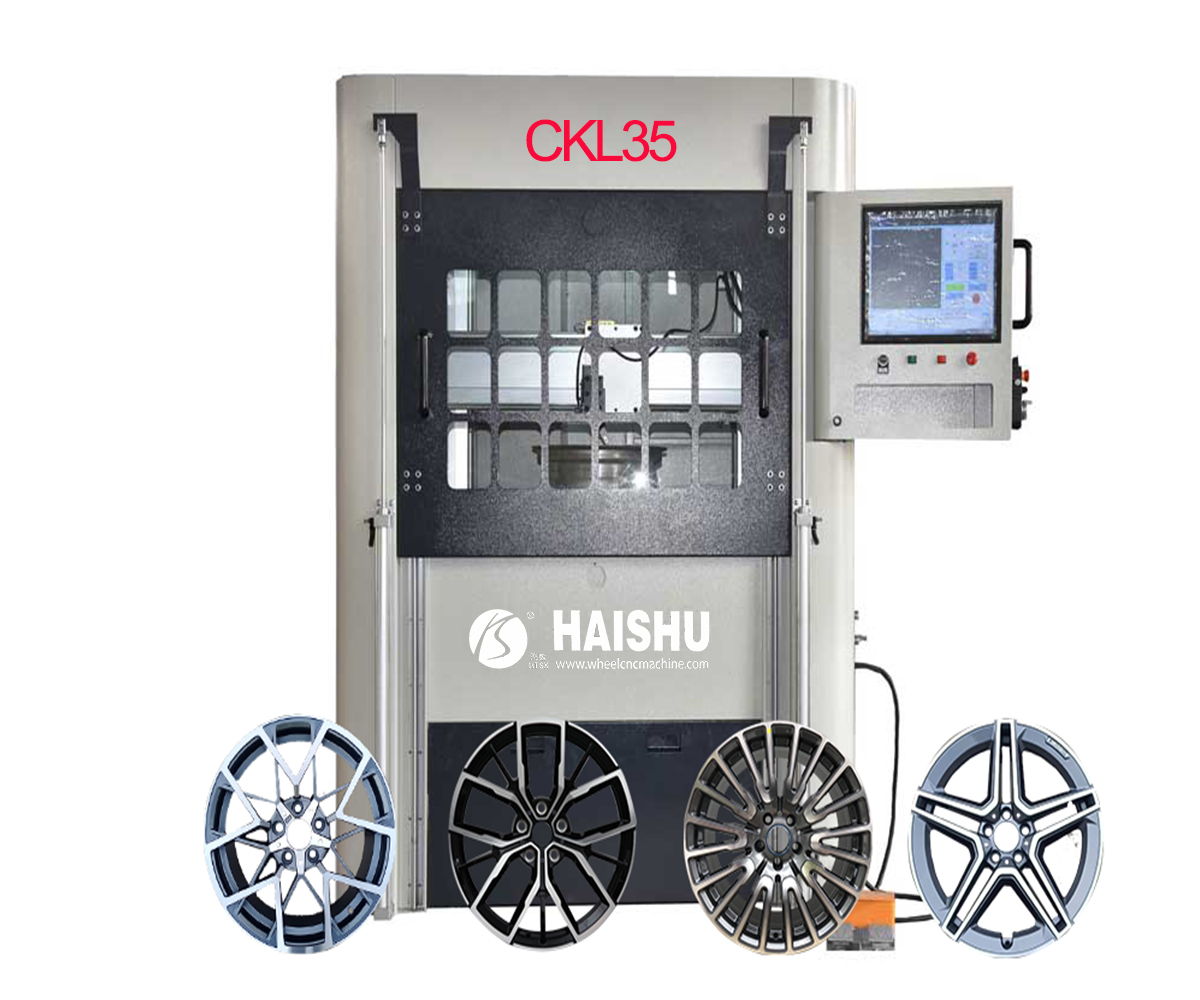

Alloy Wheel Polishing Machine CK6180W: Advanced Features for Precision and Efficiency

The CK6180W Alloy Wheel Polishing Machine is equipped with a range of advanced features to ensure fast and precise wheel polishing. Here are the key features that make this machine stand out:

- Laser Scanning for Fast Measurement: The machine utilizes laser scanning technology, enabling quick and accurate measurement of the wheel dimensions and shape.

- Automatic Storage of Wheel Data: The wheel data is automatically stored in the machine’s memory, allowing for easy retrieval and recall of machining programs.

- Independent Software Development: The machine features independently developed software that automatically optimizes the machining program, ensuring efficient and effective wheel processing.

- Automatic Precise and Fast Processing: With its advanced automation capabilities, the CK6180W achieves precise and rapid wheel processing, saving time and increasing productivity.

- User-Friendly Touch Screen Operation: The machine is equipped with a user-friendly touch screen interface that supports multiple languages, making it easy to operate.

- X/Z Axis Measurement and Machining: The CK6180W allows for measurement and machining of the wheel surface and circumferential areas through its X and Z axes, ensuring comprehensive polishing.

- Three-Color Warning Lights: The machine is equipped with three-color warning lights to provide visual alerts for different operating conditions, enhancing safety and efficiency.

- Manual Pulse Generator (MPG): The inclusion of an MPG enables manual control of the machine’s movement, offering precise adjustments during the polishing process.

- Automatic Lubrication System: The CK6180W features an automatic lubrication system that ensures smooth operation and extends the machine’s lifespan.

- Diamond Cutting Capability: The machine is capable of diamond cutting, allowing for precise and high-quality wheel surface finishing.

- Wheel Polishing Function: In addition to cutting, the CK6180W also provides wheel polishing capabilities, delivering a polished and refined final appearance.

- High-Configuration Internal and External Protection: The machine is equipped with comprehensive internal and external protection measures, ensuring operator safety and machine longevity.

- Customization Options: The CK6180W can be customized according to specific customer requirements, allowing for tailored solutions that meet individual needs.

GUARANTEE AND AFTER-SALE SERVICES:

We stand by the quality and performance of the CK6180W Alloy Wheel Polishing Machine, offering the following guarantee and after-sale services:

- One-Year Guarantee: We provide a one-year guarantee for the entire machine, offering peace of mind and support for any potential issues.

- 24-Hour Technical Support: Our dedicated technical support team is available 24/7 to assist with any inquiries or troubleshooting via email or telephone.

- User-Friendly Software and Manuals: The machine comes with user-friendly English software, along with user manuals and detailed videos/CDs. Russian or Spanish language options are also available.

- Extra Accessories: We provide additional accessories for the machine, ensuring that you have everything necessary for optimal operation.

- Customized Program Service: Our team can create customized machining programs based on your specific wheel designs and requirements.

- Customization and Special Design: We offer the flexibility to customize the machine or provide special designs to meet unique customer needs.

The CK6180W Alloy Wheel Polishing Machine is designed to deliver exceptional precision, efficiency, and reliability in alloy wheel polishing operations. Trust in our machine and enjoy the comprehensive support we provide for a seamless experience.

About HAISHU Machinery

With more than 17 years of experience in the industry, we are a leading manufacturer of Wheel CNC Machines. Our expertise lies in the development, production, and export of Wheel Repair Lathes, Wheel Repair Machines, and Drum Brake Lathes. Our products have gained widespread recognition and have been successfully sold in over 50 countries worldwide.

We are committed to maintaining the highest standards of quality, and as such, our company has obtained ISO9001 quality system certification and CE certification. These certifications serve as a testament to our dedication to delivering reliable and high-performance machines to our customers.

Our team of professionals combines technical expertise with innovative design, ensuring that our Wheel CNC Machines meet the specific requirements of our clients. We strive for excellence in every aspect of our operations, from product development to customer service, making us a trusted choice in the industry.

By choosing our Wheel CNC Machines, customers can expect superior quality, advanced technology, and excellent performance, backed by our years of experience and commitment to customer satisfaction.