Wheels Repair Machine CK6166Q: Revolutionizing Wheel Machining in Vietnam

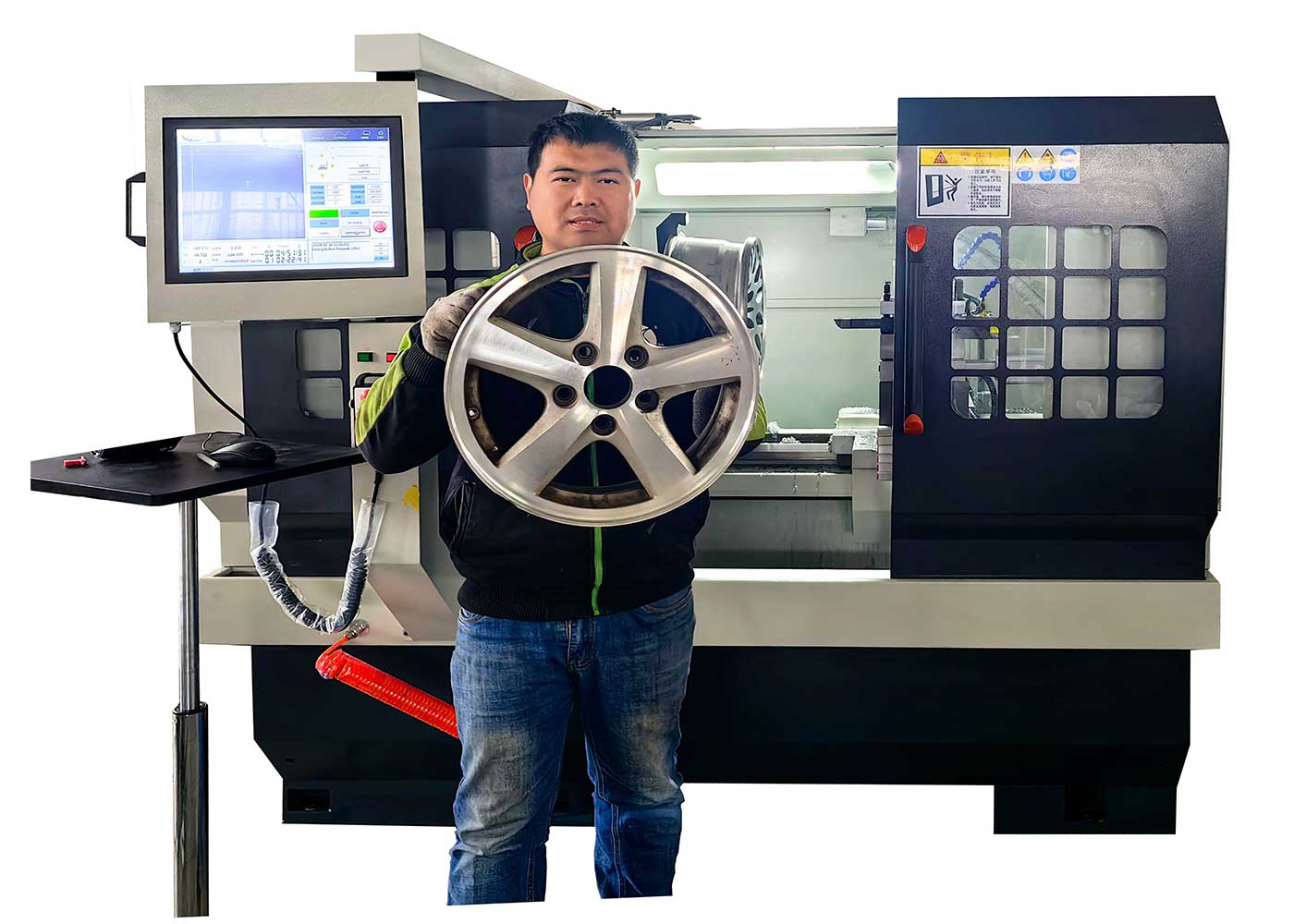

Introduction to the Advanced Wheels Repair Machine CK6166Q

In the bustling automotive industry, the need for efficient and reliable wheel repair solutions is ever-increasing. The Wheels Repair Machine CK6166Q, a standout product in the wheel CNC machine market, is designed to meet this demand with precision and ease. This machine is a hot sale item, particularly for its automatic features that simplify the wheel machining process.

Seamless Operation with the Wheel Repair CNC Lathe

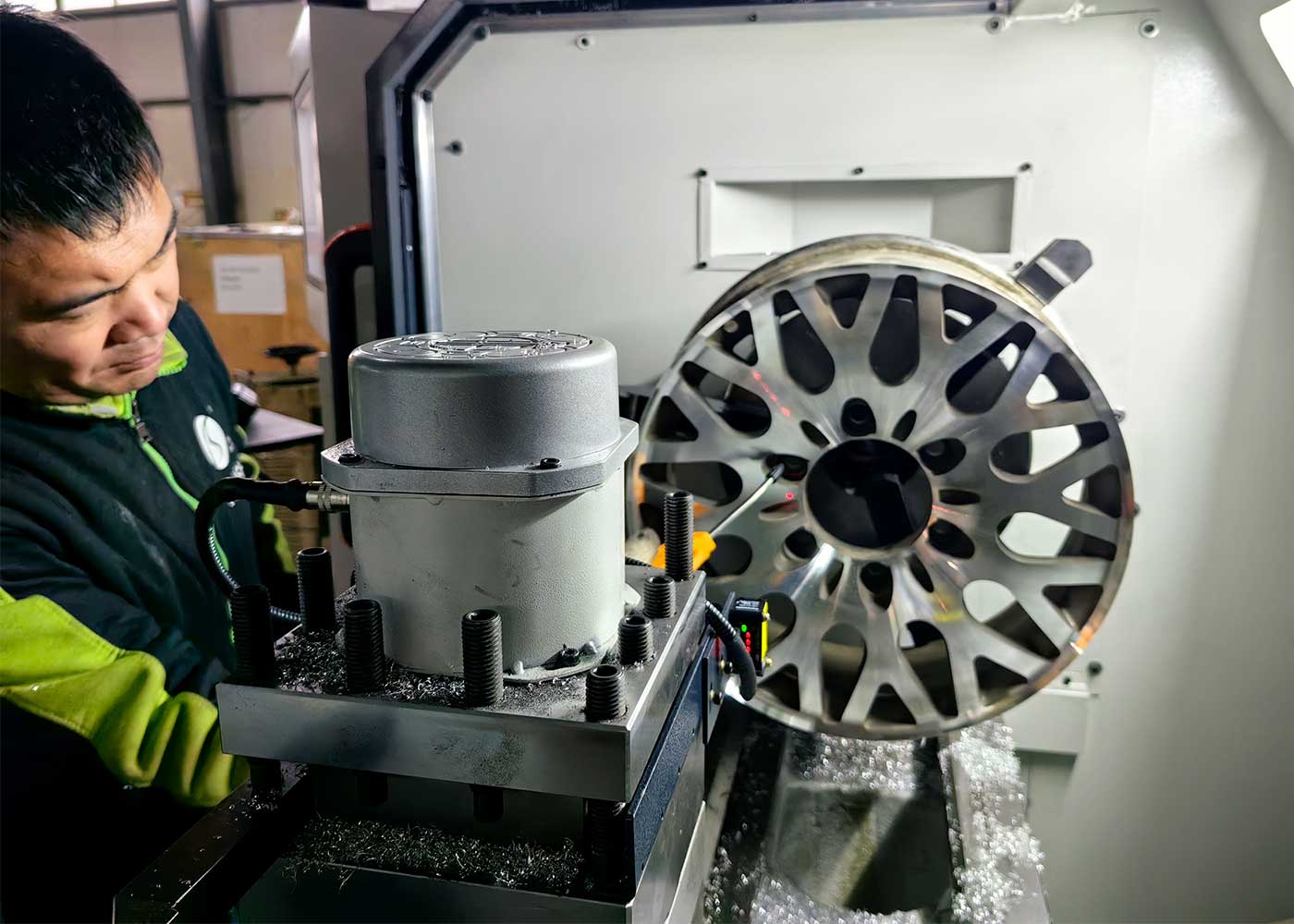

Automated Scanning and Detection

The Wheel Repair CNC Lathe CK6166Q comes equipped with an automatic scanning and detection programming system, which has advanced from the original wheel-turning machines. This innovation eliminates the need for manual curve measurement programming, making the process quicker and reducing the chances of human error.

User-Friendly Interface

Despite its sophisticated technology, the CK6166Q is renowned for its fast operation speed and simple operation, making it accessible to users with no prior experience. The intuitive touch screen and multilingual support, including English and Vietnamese, ensure that learning and operating the machine is a straightforward experience.

The Fully Automated Wheel Restoration Machine

Assisted Learning for New Operators

Understanding the apprehensions of customers unfamiliar with such advanced wheel repair lathe, the company provides comprehensive online video tutorials demonstrating the operation process. This proactive customer service approach ensures that even those new to the machine can perform wheel repair with confidence, as evidenced by a Vietnamese client who, after witnessing the ease of operation, proceeded with the purchase.

Customization and Satisfaction

Tailoring to specific customer needs, Haishu Machinery offers customization in both language and machine specifications. The CK6166Q model was selected by the Vietnamese client, who was pleased with the customization options and swift contract and payment processes.

Main Features of the Alloy Wheel Repair Machine CK6166Q

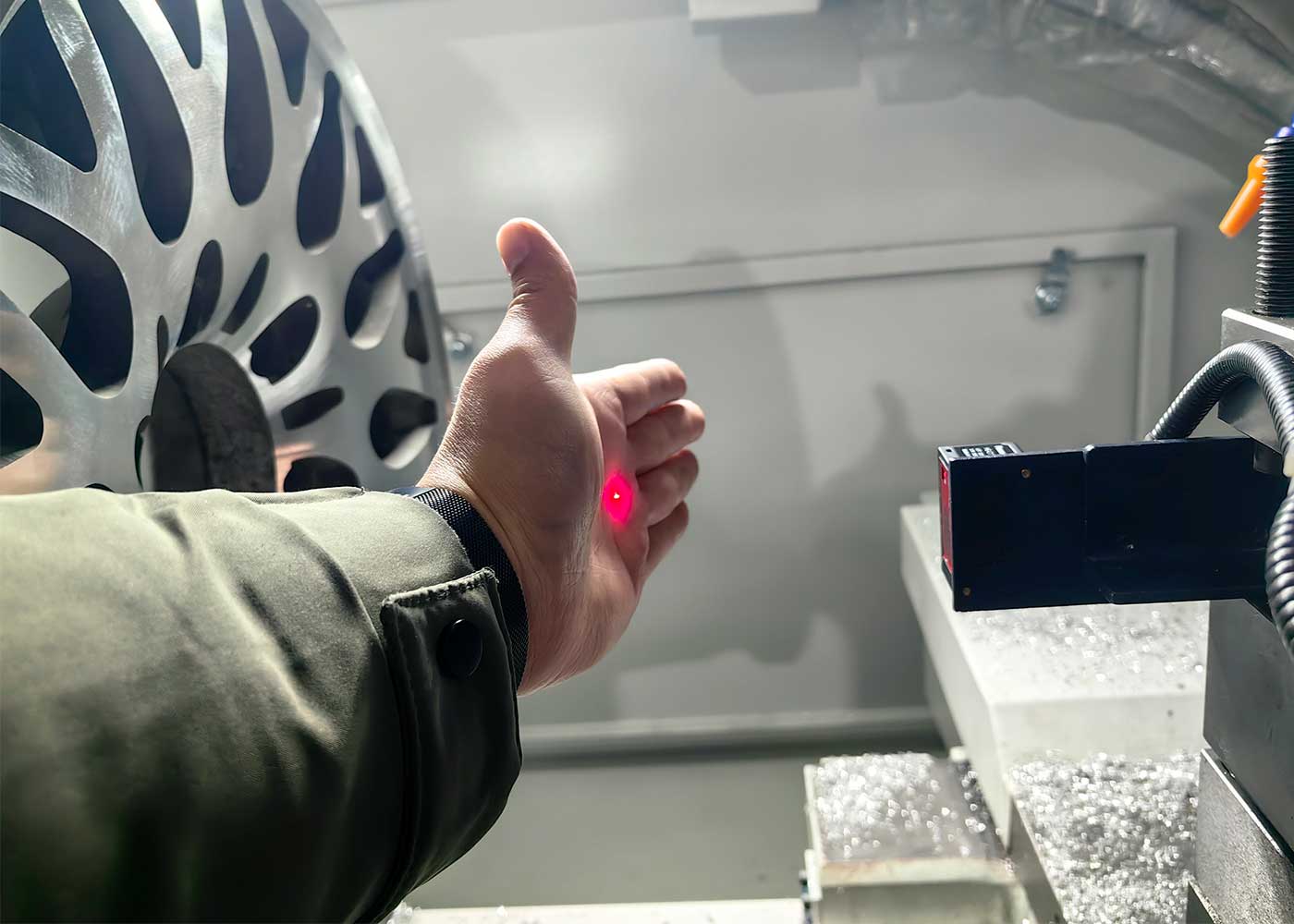

High Precision with Laser Scanning Technology

The use of laser scanning for wheel surface measurement allows for pinpoint accuracy, whether it’s a single point, a line, or a curve. The spindle drive, powered by a servo motor and synchronized belt, along with digital drive implementation, ensures the precision of the machine.

Innovative CNC System

Developed specifically for wheel repair, the CNC system and optimization software are robust and feature-rich, catering to the specialized needs of wheel refurbishment. The system’s hard disk boasts an impressive storage capacity, capable of storing data for up to 100,000 wheel programs.

Convenience and Efficiency

The Rim Repair Equipment optimizes programs automatically or manually, making operations flexible and user-friendly. Additionally, the system allows for quick retrieval of stored wheel data for repetitive repairs on wheels of the same type.

Enhanced Operational Safety and Customization

Full Protective Cover and Safety Features

The machine is designed with operator safety in mind, equipped with a new full protective cover and rail sliding doors. It also features a spacious working area, fault alarm light, and an automatic lubrication system, enhancing the overall safety and maintenance of the machine.

Diamond Cutting and Polishing

The Alloy Wheel Diamond Cutting Machine aspect of the CK6166Q ensures a polished finish for the repaired wheels, providing an additional service that adds value to the wheel refurbishment process.

Versatility and Customization

Meeting Diverse Requirements

With a range of specifications, the machine can handle wheel diameters from 5 to 35 inches, making it versatile for different wheel sizes. Customization options extend to the machine’s appearance and configuration, catering to the unique preferences of various customers.

About Haishu Machinery

Haishu Machinery, with its dedicated technology development departments and professional technicians, commits to providing exceptional services. The company offers a wide array of products, including the Wheels Repair Machine CK6166Q, Rim Straightening Machine, and various other wheel repair solutions for the automotive aftermarket. Upholding principles of integrity and quality, Haishu Machinery is poised to collaborate closely with partners, offering flexible business models and high-quality services. The company eagerly anticipates establishing long-term relationships with clients, reinforcing its position as a trusted name in the wheel repair industry.