Unveiling the Precision of HAISHU’s Diamond Cut Wheel Machines: CK6160Q and CKL22Q

Transforming Wheel Refurbishment with Advanced Technology

What is a Diamond Cut Wheel Machine?

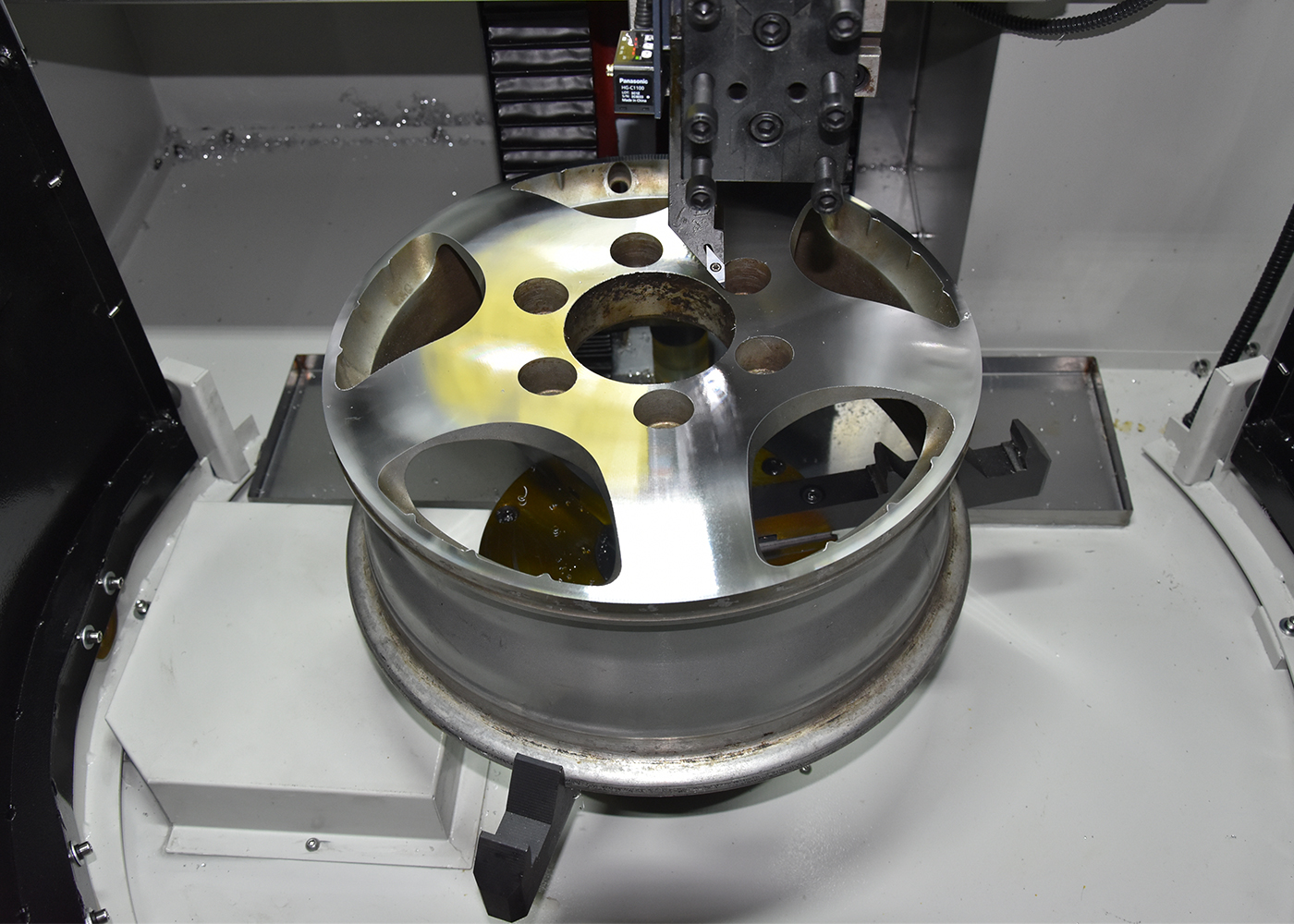

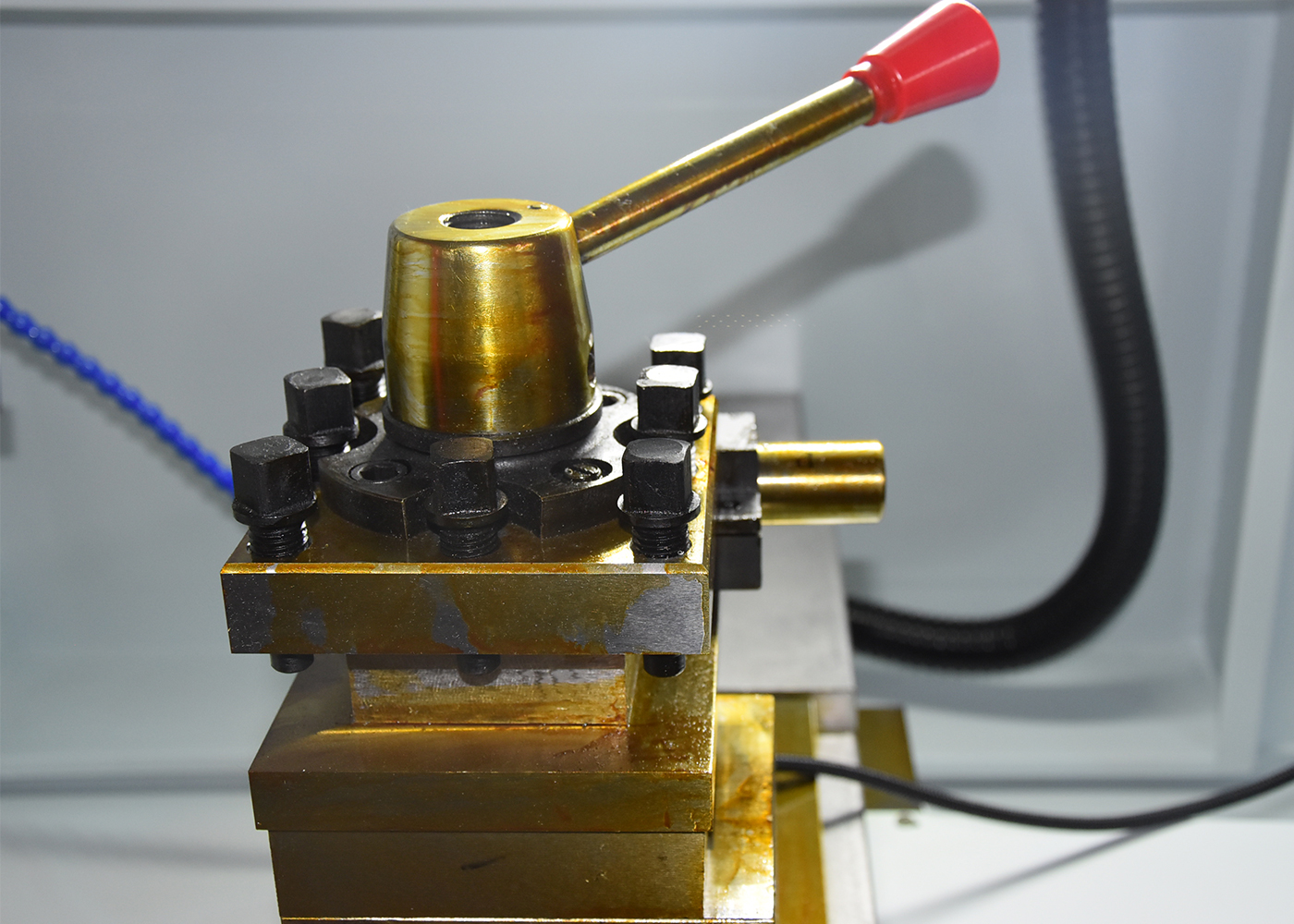

A Diamond Cut Wheel Machine is an advanced type of wheel CNC machine employed in the automotive industry for refurbishing alloy wheels. It uses a precision-engineered diamond-tipped cutter to shave off a thin layer of metal from the wheel’s surface, achieving a glossy, high-quality finish that is highly sought after in the market.

How Does HAISHU’s CK6160Q Elevate the Wheel Refurbishing Process?

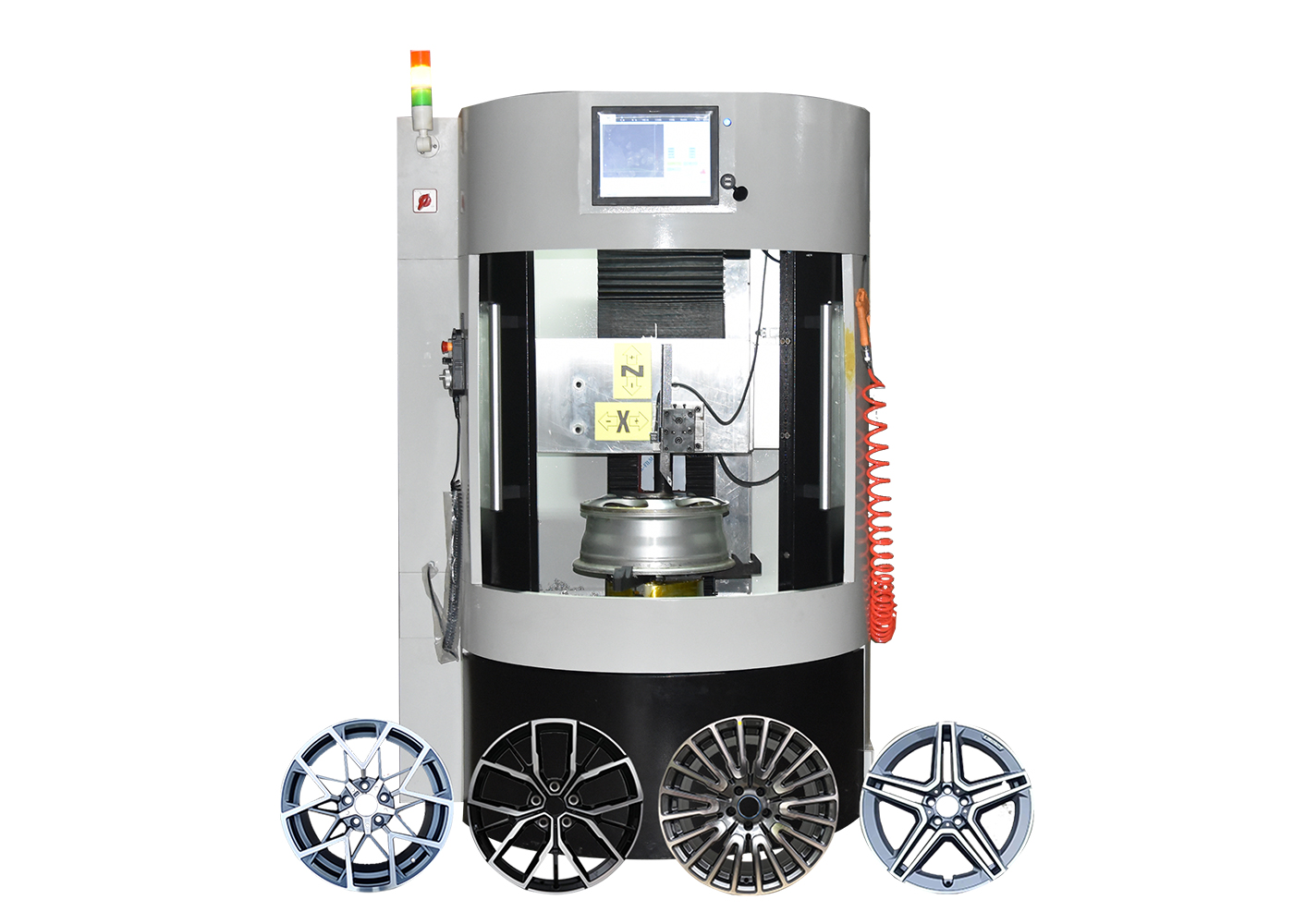

HAISHU’s CK6160Q is a state-of-the-art Diamond Cut Wheel Machine designed for precision and ease of use. It features an optimized structure for wheel repair, providing a stable and reliable foundation for high-precision machining. The CK6160Q is equipped with advanced automation features like laser detection, a user-friendly interface, and the ability to handle wheels up to 26 inches, making it a versatile choice for workshops looking to expand their service offerings.

What Makes the CKL22Q a Standout Wheel Repair Machine?

The CKL22Q is another exceptional offering from HAISHU, designed for those who require a more compact solution without sacrificing performance. Its smaller footprint makes it ideal for shops with limited space but still offers the same high precision and automation features found in larger models. With its capability to repair up to 22-inch wheels, the CKL22Q is perfect for handling a wide array of wheel refurbishing tasks.

The Advantages of Integrating Wheel CNC Machines in Workshops

Why Should Workshops Invest in a Wheel Repair Lathe?

Investing in a wheel repair lathe can significantly enhance a workshop’s capabilities. These machines not only allow for the repair of damaged wheels but also provide a cost-effective solution to customers, as opposed to the expense of purchasing new wheels. The addition of a wheel repair lathe to a workshop’s arsenal means being able to offer a lucrative service that can pay dividends in customer satisfaction and repeat business.

How Do HAISHU’s Machines Provide a Competitive Edge?

HAISHU’s machines, such as the CK6160Q and CKL22Q, provide a competitive edge through their exceptional precision, speed, and user-friendly operation. Their automated systems reduce the margin for error and produce consistent, high-quality finishes. By reducing labor costs and enhancing the quality of service, these machines can help workshops to stand out in a crowded market.

The Technical Excellence of HAISHU’s Diamond Cut Wheel Machines

What Technical Specifications Should One Look for in a Wheel CNC Machine?

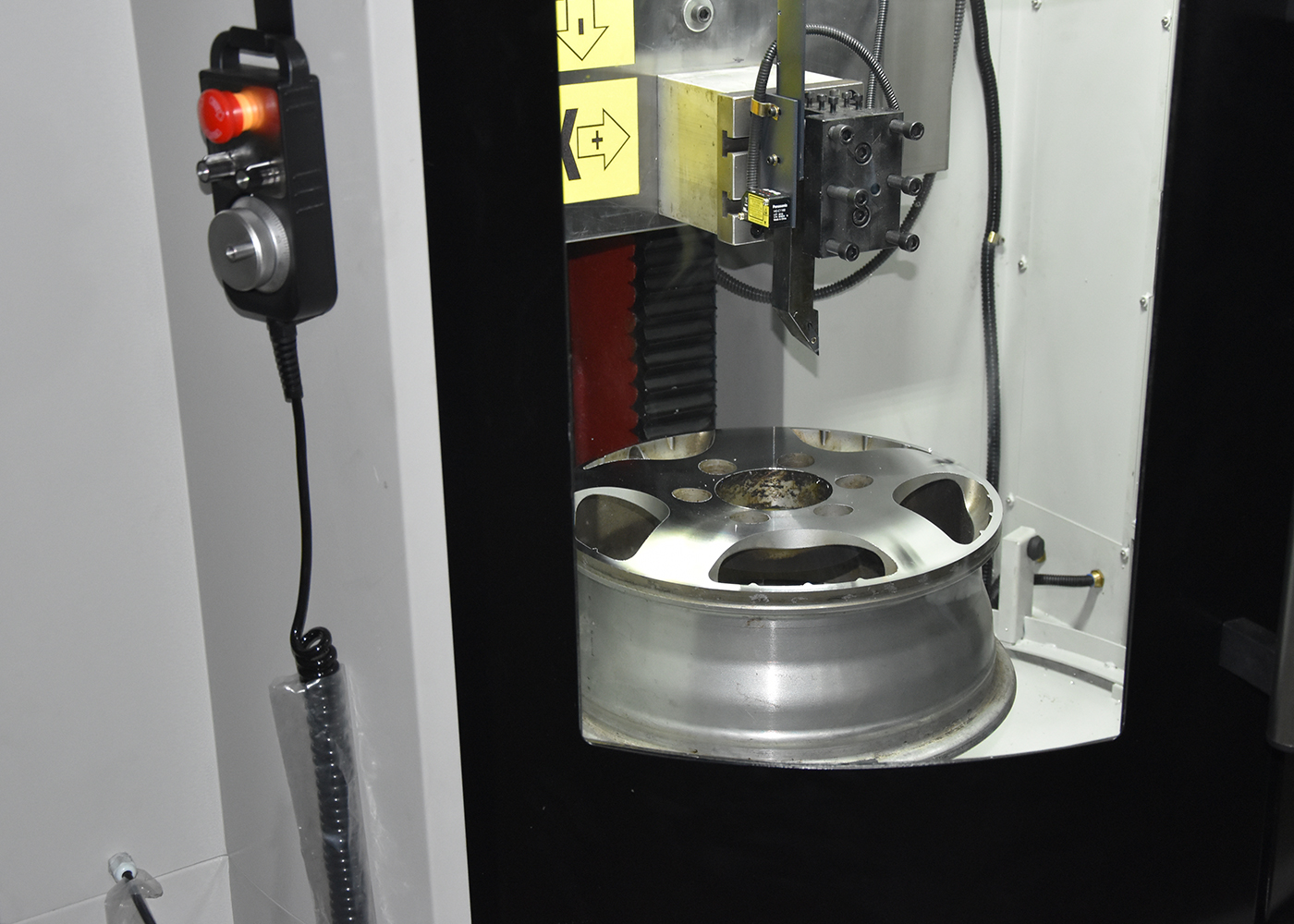

When considering a wheel CNC machine, it’s essential to look at the maximum wheel size capacity, the precision of the cutting tool, software capabilities, and the quality of the components used in the machine. Features like automatic tool changers, laser scanning, and touchscreen controls can also greatly enhance the machine’s functionality.

How Do Automation and Precision Coalesce in HAISHU’s Wheel Repair Machines?

HAISHU’s wheel repair machines, such as the CK6160Q and CKL22Q, integrate automation and precision to deliver a high-quality finish with minimal input from the operator. Automation ensures consistent cutting and reproducibility, while precision engineering guarantees that each wheel is refurbished to exacting standards, restoring it to its original appearance or better.

Maximizing Workshop Potential with HAISHU’s Offerings

How Can Workshops Benefit from the CK6160Q and CKL22Q Models?

Workshops can benefit from the CK6160Q and CKL22Q models by offering high-end alloy wheel refurbishment services. These machines cater to a broad spectrum of wheel sizes and types, ensuring that a workshop can accommodate most customer requirements. The efficiency and precision of these machines also mean that shops can turn around jobs quicker, increasing customer satisfaction and throughput.

What Type of After-Sales Support Does HAISHU Provide?

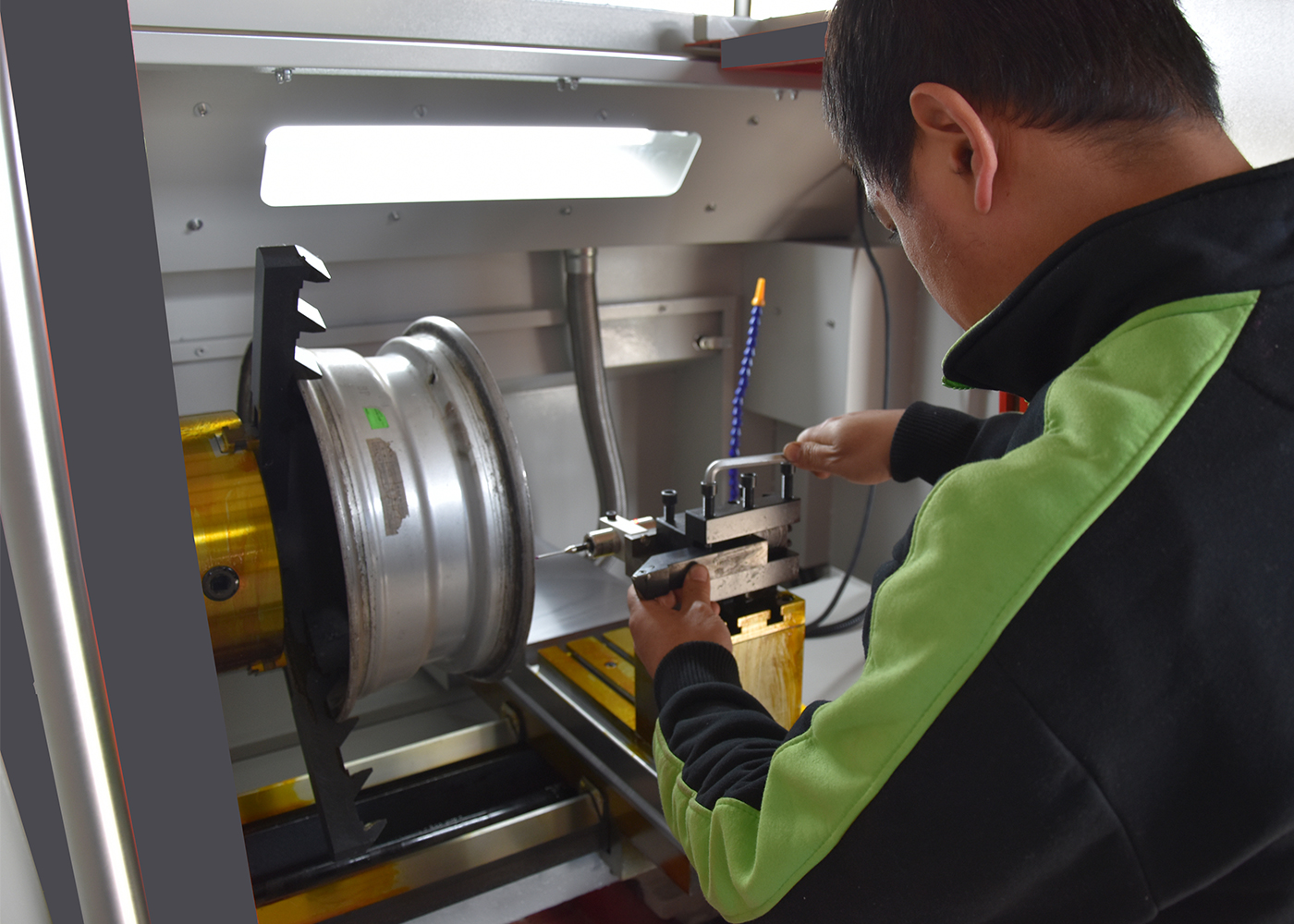

HAISHU is known for its comprehensive after-sales support, which includes technical assistance, training for operators, and a reliable supply of spare parts. This ensures that customers can maintain their machines in optimal condition, reducing downtime and preserving the quality of their services.

Concluding Thoughts on the Investment in Diamond Cut Wheel Machines

Why is the Purchase of a Diamond Cut Wheel Machine a Wise Decision for Wheel Refurbishment Services?

The purchase of a Diamond Cut Wheel Machine is a wise decision due to the growing demand for diamond-cut wheel finishes. By offering this service, workshops can tap into a niche market, differentiating themselves from competitors and attracting customers seeking high-quality results.

How Can HAISHU’s CK6160Q and CKL22Q Boost Return on Investment?

HAISHU’s CK6160Q and CKL22Q machines can boost return on investment by enabling workshops to offer a premium service with a high-profit potential. The durability and efficiency of these machines also mean that they are a long-term investment that can continue to generate revenue for years to come# Diamond Cut Wheel Machines: The Path to Premium Wheel Refurbishment

Unveiling HAISHU’s CK6160Q and CKL22Q

What Are Diamond Cut Wheel Machines?

Diamond cut wheel machines are specialized wheel CNC machines designed to refurbish wheels with a decorative finish that resembles the face of a diamond. These machines use precision lathes and diamond-tipped cutting tools to create fine, precise cuts on the wheel surface, resulting in a high-shine, attractive finish.

Why Choose HAISHU’s CK6160Q for Your Business?

HAISHU’s CK6160Q is a robust and reliable wheel repair machine that brings efficiency and precision to your wheel refurbishing services. It’s capable of handling wheels up to 26 inches, making it suitable for a wide range of vehicles. With features like a self-developed CNC system and automatic detection, the CK6160Q ensures high-quality finishes with minimal effort.

How Does the CKL22Q Enhance Wheel Refurbishment Services?

The CKL22Q, another innovative product from HAISHU, is designed for ease of use without compromising on quality. Its compact design is perfect for smaller spaces, and it still offers the same precision and functionality as larger models, catering to wheels up to 22 inches. This machine is ideal for businesses that want to provide exceptional service but have limited workshop space.

The Significance of Wheel Repair Lathes in Modern Workshops

Can a Wheel Repair Lathe Transform Your Workshop’s Offerings?

Absolutely. A wheel repair lathe can dramatically expand your service capabilities, allowing you to repair and refurbish alloy wheels with accuracy and speed. This not only increases your customer base but also adds a lucrative revenue stream to your business.

What Unique Benefits Do HAISHU Machines Provide?

HAISHU machines, such as the CK6160Q and CKL22Q, offer unparalleled precision, durability, and ease of use. With automated features and advanced technology, these machines reduce the time and skill required to produce high-quality wheel refurbishments.

Technical Aspects and Considerations

What Technical Features Should You Consider in a Wheel CNC Machine?

When considering a wheel CNC machine, important features include the maximum wheel size, the precision level of the cutting process, software integration, and automation capabilities. HAISHU’s machines offer these features, ensuring they meet the diverse needs of modern wheel refurbishment businesses.

How Do HAISHU’s Machines Integrate Automation and Precision?

HAISHU’s wheel repair machines integrate automation through features like automatic probing and software that can calculate precise cutting paths. This level of automation ensures that each wheel is cut with exacting precision, resulting in a consistently high-quality finish.

Making the Right Investment for Your Workshop

What Makes the CK6160Q and CKL22Q Models a Smart Investment?

The CK6160Q and CKL22Q models are smart investments for workshops looking to offer high-end alloy wheel refurbishment services. Their ability to handle a wide range of wheel sizes, combined with advanced features, ensures that your business can cater to a broad customer base.

What After-Sales Support Can You Expect from HAISHU?

HAISHU provides comprehensive after-sales support, including technical assistance, operator training, and a dependable supply of spare parts. This level of support helps to minimize downtime and ensures that your HAISHU machines continue to operate at peak performance.

Final Thoughts on Diamond Cut Wheel Machines

Why Should Workshops Invest in Diamond Cut Wheel Machines?

Investing in diamond cut wheel machines is a strategic move for any workshop looking to differentiate itself in the market. These machines enable the delivery of high-quality, in-demand finishes that can significantly boost a business’s reputation and profitability.

How Do HAISHU’s CK6160Q and CKL22Q Maximize ROI?

HAISHU’s CK6160Q and CKL22Q machines maximize return on investment by providing fast, precise, and efficient wheel refurbishing services. Their durability and advanced features mean they’re a cost-effective solution that can help a workshop to quickly recoup its investment and generate substantial profits over time.