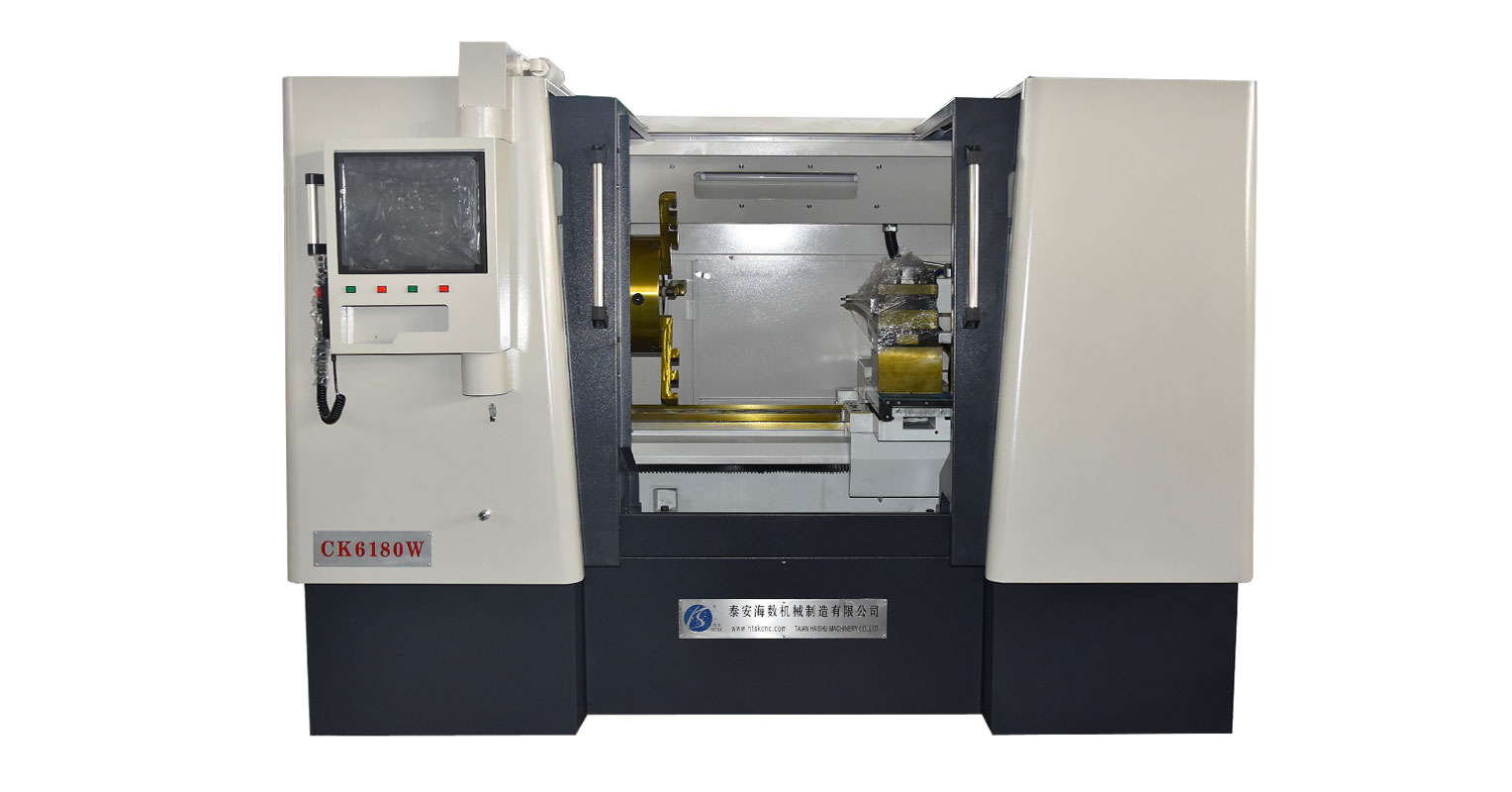

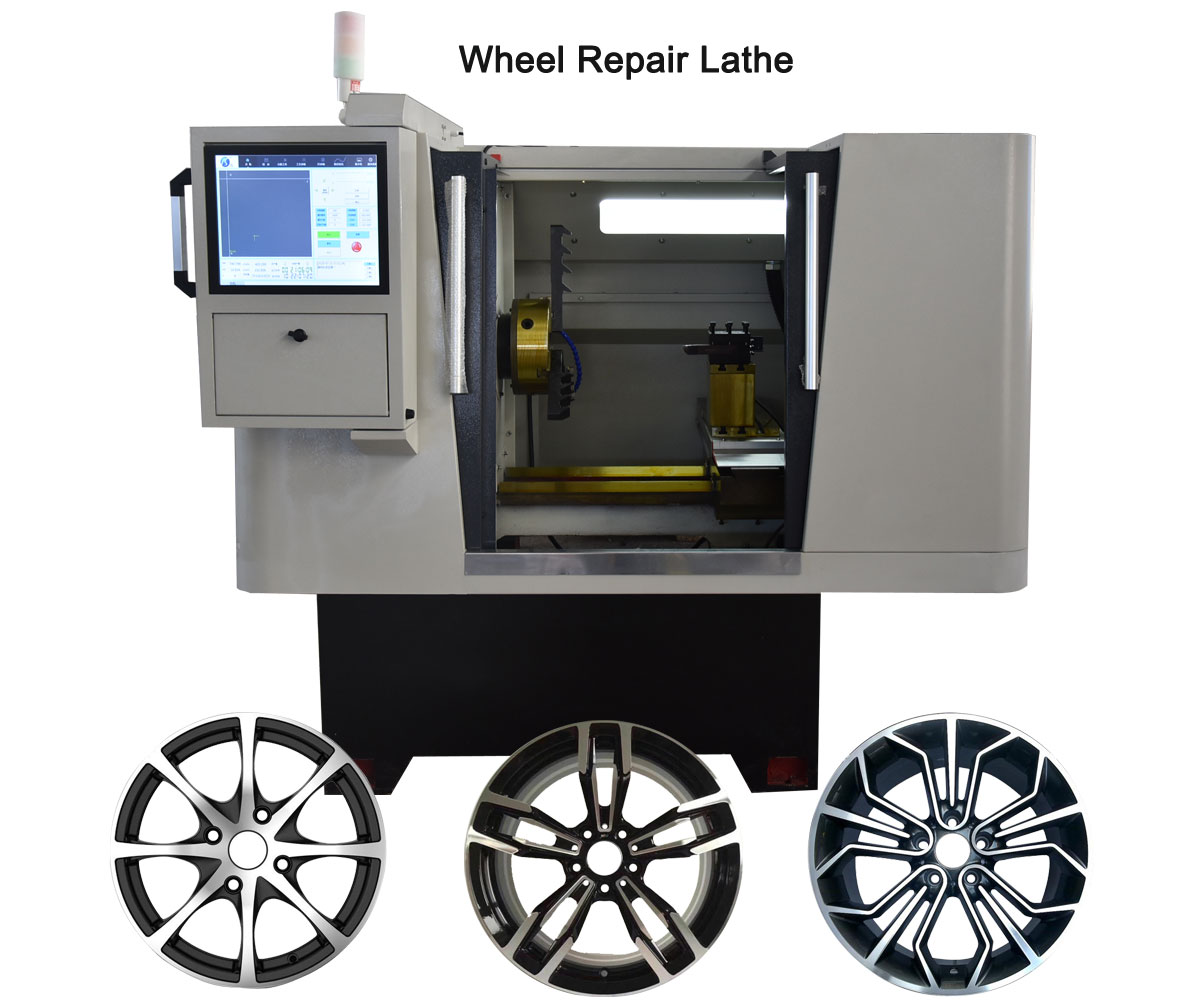

Advanced wheel lathe is a CNC lathe specially used to repair scratches on car wheels or beautify car wheels. The emergence of wheel repair machine tools has greatly improved processing efficiency. The advanced wheel lathe is the ideal wheel repair lathe for workers to master the repair skills within 30 minutes and operate proficiently. Taian HAISHU’s wheel hub repair lathe has its own dedicated wheel hub system, and it has been upgraded to the latest version. The customized systems can be used in European and American countries, South Korea, and many developing countries Allow them to define in their own language.

The advanced wheel hub repair lathe has been developed for the third generation. The main functions have been related to wheel detection, curve optimization, and automatic processing.

The first generation of wheel hub lathe is a purely manual operation. After manual clamping is completed, the tool is used to cut bit by bit. The efficiency is very low and the effect is not achieved. The second belt of the hub lathe machine only uses the numerical control system, which improves the processing efficiency. However, the detection efficiency for automobile wheels is still very slow. The third generation of the wheel repair lathe has broken the bottleneck of wheel detection and can use laser probes and contact probes. Different detection methods are adopted for different wheels, which improves the detection efficiency and increases the repair effect of the wheels.

What Are the Configurations Of Advanced Wheel Repair Lathe

- The wheel repair machine adopts HAISHHU special CNC wheel software. Our engineers took two years to combine wheel detection and curve optimization. It directly realizes the automatic detection of the wheel hub, the automatic optimization of the curve, and the automatic processing of the machine. It is efficient and safe.

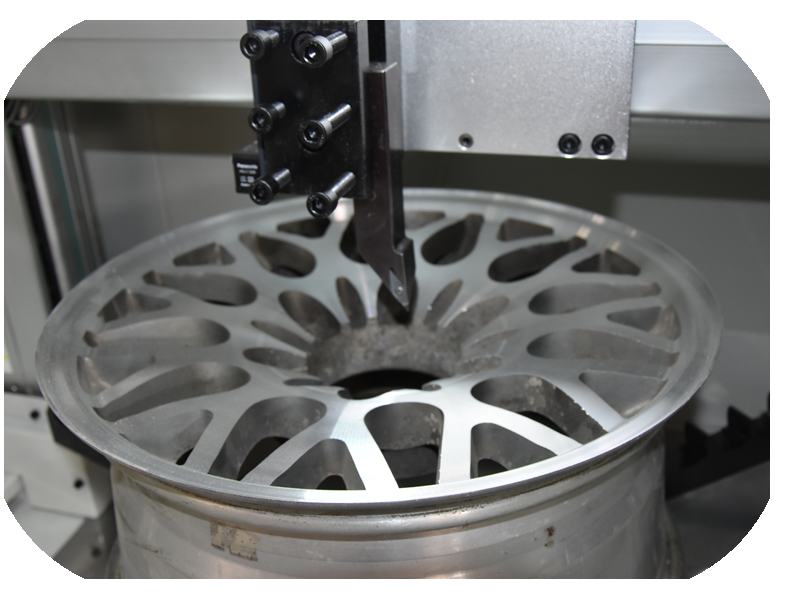

- The wheel hub lathe is equipped with a laser probe, it only takes 10-15 seconds to complete the wheel surface detection. And it is also very suitable for wheels with a large height difference.

- The advanced wheel lathe can also be equipped with contact probes. The only disadvantage is that the detection time is long and the efficiency is slow. The current mainstream detection method is laser detection.

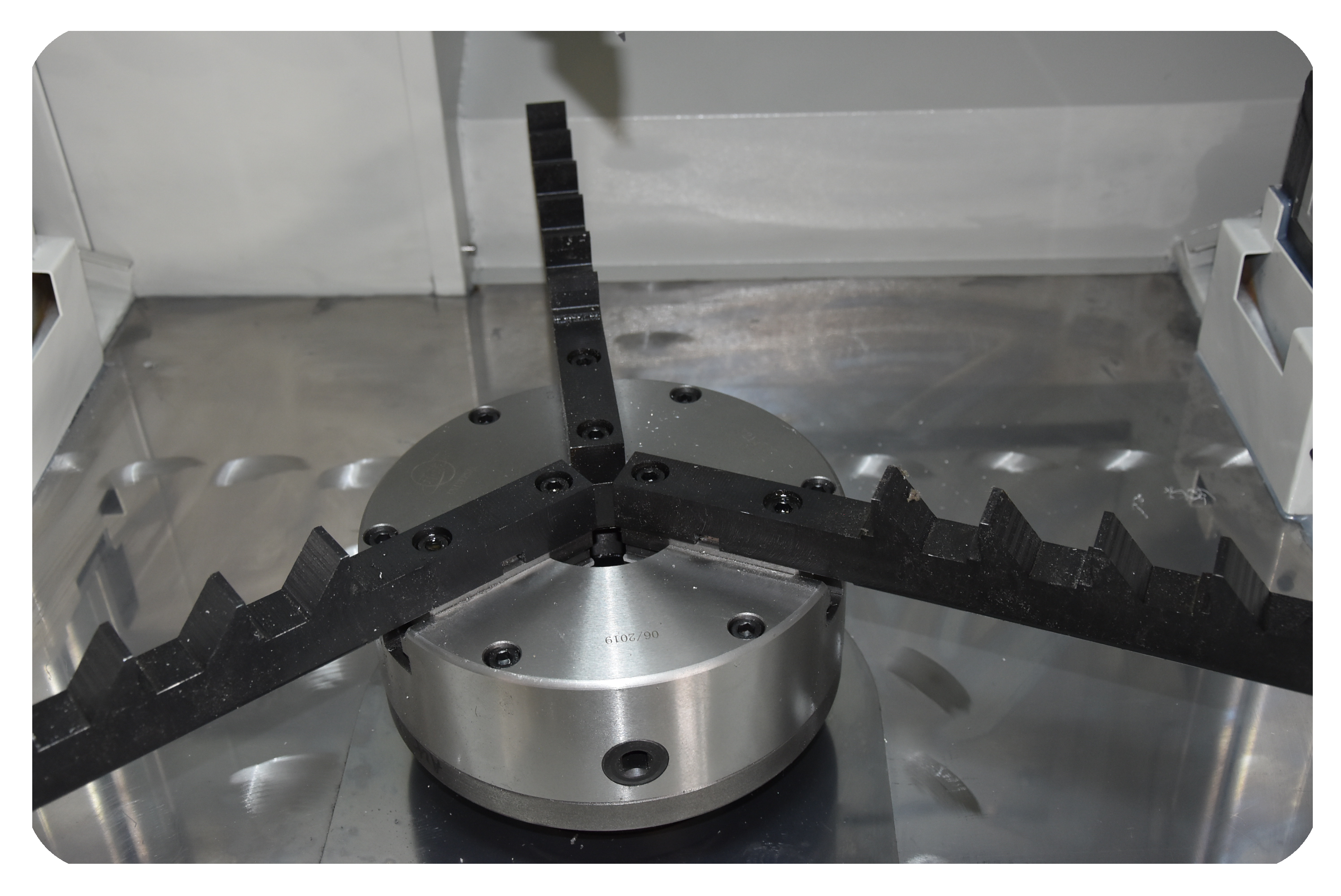

- The CNC wheel hub lathe adopts a special wheel hub fixture, which is clamped with extended claws, which is highly efficient and completely stable. You can also use the center positioning method for clamping. The disadvantage is that the clamping efficiency is slow and manual correction is required.

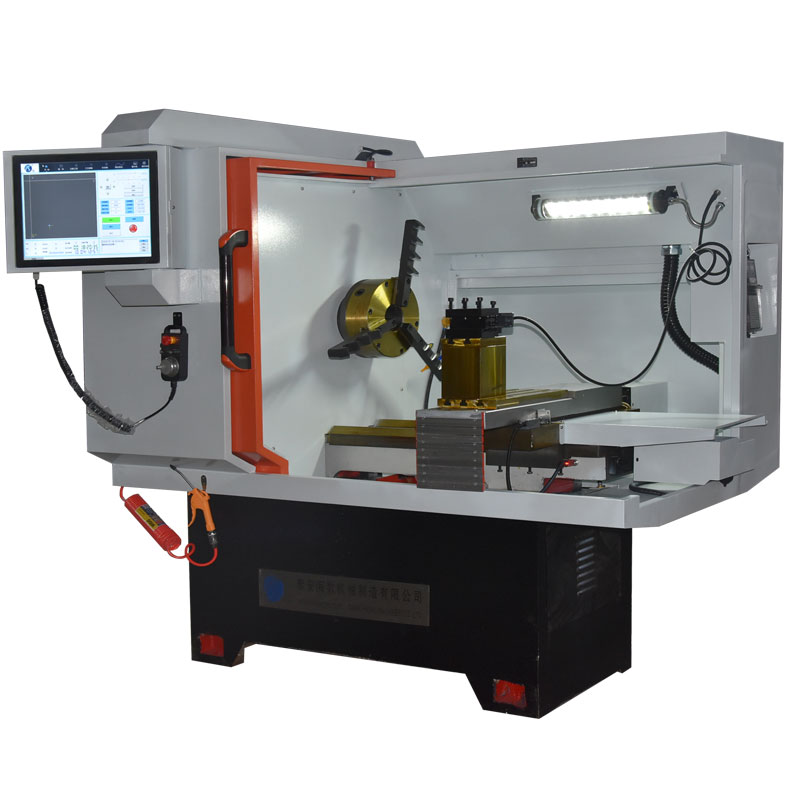

- Safety door can increase the safety of equipment operation, HAISHU wheel lathe has specially added safety door function for customers. That is, in the process of processing, once the protective door is opened, the machine immediately stops running and sends out an alarm. If the protective door is not closed, the advanced wheel hub repair lathe will not operate

- Touch screen design. The operating system of the entire wheel hub CNC lathe is a touch screen. Very easy to click and modify

- Curve optimization. After the car wheel repair lathe detects the surface of the wheel, it can be automatically optimized with one button, which is convenient and fast

- The air gun is for the customer to use the air source to clean the machine after finishing the work on the wheel hub repair lathe, and it is efficient and tidy.

- Fully automatic lubrication and lighting. The lubrication unit will automatically lubricate at the specified time. Ensure that the machine can be fully maintained. And the lighting will automatically turn on to provide good light for customer operations.

- Lifetime free upgrade service. If the software of the HAISHU wheel lathe is upgraded, we will provide customers with a free upgrade service, which is valid for life.

What Are the Advantages Of Advanced Wheel Repair Lathe

- The CNC wheel hub lathe is efficient and fast and can complete the detection in 10 seconds

- Vertical wheel hub lathe and horizontal wheel hub lathe can be fully automated, allowing workers to master within 30 minutes

- The aluminum alloy wheel hub lathe is fast and convenient for clamping, using a dedicated wheel hub clamping method

- The wheel hub lathe is safe and efficient and adopts a safety door design, which can automatically alarm to ensure the safety of workers 5. On-site service is available, and the professional service team can provide on-site service for you

- A variety of detection methods, the hub lathe can use laser detection or probe detection, both can also be installed at the same time

- The tool post of the wheel hub CNC lathe can be divided into simple tool post, manual tool post, and electric tool post

- The wheel lathe nameplate can be customized for customers

- Global language customization. CNC wheel hub lathe can provide customized language for customers, using their respective national languages.

- Voltage customization. If your country’s voltage is different from ours, there is no problem. We can change the voltage for you. Our wheel lathe is currently the most advanced in the world.

About HAISHU Machinery

HAISHU is a manufacturer specializing in manufacturing and selling wheel repair lathes. It has sales or customers in more than 90 countries and regions around the world. Our wheel hub lathe adopts laser detection, which is very advanced. I hope you can visit our website or visit our company