What Does The Alloy Wheel Machine CK6160Q Look Like?

The CK6160Q Alloy Wheel Machine is a robust and powerful Wheel CNC machine designed specifically for alloy car wheel hub repair, refurbishment, machining, super-finishing, and maintenance. This machine offers exceptional capabilities and features that enhance the efficiency and precision of the wheel repair process.

Equipped with advanced technology, the alloy wheel lathe machine can perform laser scanning to accurately analyze the condition of the wheel surface. The touch screen interface allows for intuitive and user-friendly operation, simplifying the machining process. The machine also supports software development, enabling customization and adaptation to specific repair requirements. Regular software upgrades are available, ensuring access to the latest features and enhancements. Additionally, the machine offers multi-language support, catering to a diverse range of users.

With a focus on quality, the CK6160Q Alloy Wheel repair lathe delivers excellent performance and reliability. Its robust construction ensures durability and longevity, while the advanced features make the operation more convenient and efficient. Whether it’s repairing minor damages or performing comprehensive refurbishments, this machine is equipped to handle a wide range of wheel repair tasks.

Choose the CK6160Q Alloy Wheel Machine for superior quality, precise operation, and enhanced productivity in alloy car wheel hub repair and maintenance.

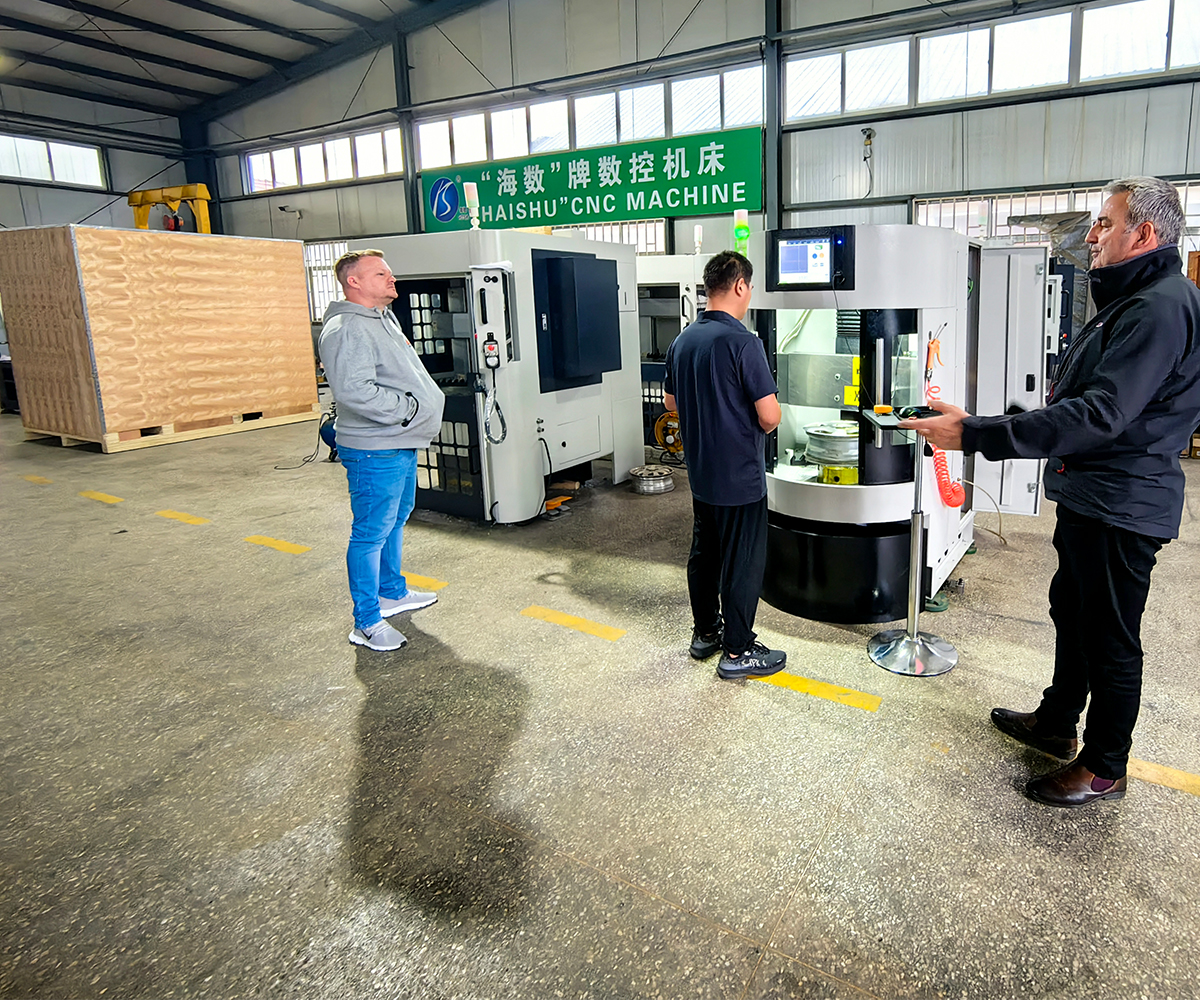

Reason For The UK Customer’s Purchase Of The Alloy Wheel Machine CK6160Q.

Regarding the Alloy wheel machine CK6160Q, a British customer approached me with several inquiries. They were interested in the machine’s model and expressed their desire to purchase the smallest machine capable of processing the largest wheel hubs. In response, I assured them that the machine could indeed fulfill their requirements. However, I also cautioned that continuous processing of large-size wheel hubs could potentially reduce the machine’s service life.

The customer appreciated my transparent and honest response, as well as the assistance provided. It’s important to address such concerns and provide customers with accurate information to ensure they make informed decisions. By offering helpful guidance, we can establish trust and maintain a positive relationship with our valued customers.

The Alloy wheel machine CK6160Q is designed to meet a range of wheel repair needs, including the processing of various wheel hub sizes. While it can handle larger wheel hubs, it’s essential to consider the long-term impact on the machine’s longevity. By providing customers with comprehensive information, we aim to assist them in making the most suitable choices for their specific requirements.

About Alloy Wheel Machine CK6160Q And Machinery

The alloy wheel machine CK6160Q is a powerful CNC machine specifically designed for alloy car wheel hub repair, refurbishment, machining, super-finishing, and maintenance. Its main features include:

- Economy: The machine offers a cost-effective solution for wheel repair and maintenance needs.

- Laser Scanning: It incorporates laser scanning technology for fast and accurate measurement of wheel surfaces.

- Automatic Data Storage: Wheel data is automatically stored, and machining programs can be easily accessed as needed.

- Independent Software Development: The machine’s software is developed independently, allowing for automatic program optimization.

- Automatic and Precise Processing: The machine enables automatic, precise, and fast wheel processing.

- Touch Screen Operation: It features a user-friendly touch screen interface that supports multiple languages.

- X / Z Axis Measurement: The machine performs measurements and machining operations on wheel surfaces and circumferences.

- Automatic Lubrication System: It is equipped with an automatic lubrication system to ensure smooth operation and enhanced durability.

- Diamond Cutting: The machine has the capability for diamond cutting, providing high-quality finishes.

- Customization: The machine can be customized according to specific customer requirements.

As a professional CNC wheel repair machine designer and manufacturer, Taian Haishu Machinery Co., Ltd. is committed to providing comprehensive automobile production, repair, and maintenance solutions. With a team of skilled CNC experts and a state-of-the-art manufacturing workshop, we offer a wide range of CNC machines tailored to meet the needs of our global customers. Our products are exported to various countries, including Germany, Russia, Spain, India, South Korea, Malaysia, Singapore, and many more.

We strive to deliver high-quality and reliable CNC machines that meet the demands of the automotive industry worldwide.